5238-E P-212

SECTION 8 LATHE AUTO-PROGRAMMING FUNCTION (LAP)

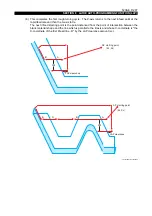

•

X-coordinate of the infeed line

≤

Bsp (X)

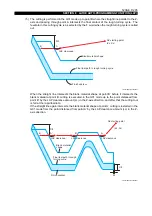

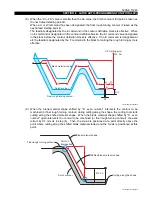

For cutting from the finish contour start point Bsp along the finish contour, the cutting tool is first

positioned in the G00 mode at the rapid feedrate at "Bsp (Z) + Lc, Bsp (X)", which is distanced

from point Bsp by the LAP clearance amount (Lc), and it is then positioned at point Bsp at a

cutting feedrate in the G01 mode.

LE33013R0301000250001

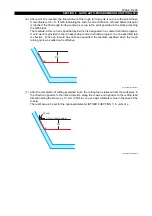

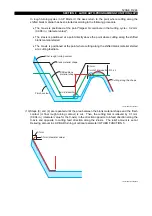

Cs (Zs) < Bsp (Z) + Lc

The portion that is to the right (in the Z-axis positive direction) of the line segment between AP

starting point Cs and finish contour start point Bsp is not cut.

Assume that the point of intersection between the infeed line and this line segment is "Xp".

•

Xp (Z) > Cp (Z) + Lc

The infeed starting point is defined at "Cp (Z) + Lc, Cp (X)", which is distanced from point Cp by

the LAP clearance amount (Lc).

•

Xp (Z)

≤

Cp (Z) + Lc

The infeed starting point is defined at point Xp (Z, X) where the line segment Cs-Bsp intersects

the infeed line.

Imaginary tool tip motion when

Cs (Zs)

≥

Bsp (Z) + Lc

Tool nose radius

Workpiece shape after the tool nose radius

compensation function has been activated

Imaginary tool tip

Blank material shape

Cp

1

Cp

2

Lc

Lc

Lc

Bsp

AP starting point

(Zs, Xs)