5238-E P-106

SECTION 7 FIXED CYCLES

Example:

For the LU300, with a peripheral speed of 100 m/min, a 10 mm diameter and a thread lead of

1.5 mm, the spindle speed and feedrate are calculated as follows.

LE33013R0300900060007

•

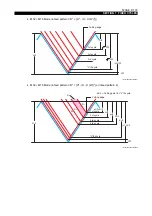

Restrictions on Cutting Speed

In a thread cutting cycle, the following restrictions apply to the relationship between spindle

speed and thread lead:

LE33013R0300900060008

[Supplement]

•

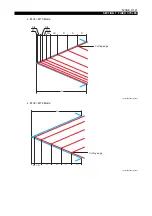

Inch System Thread

When cutting inch threads, the metric lead converted from the desired inch lead is used in

programming. To cut an accurate inch thread with the converted metric thread lead value,

either enter 8 digits below the programmable increment, 1

µ

m, or use a J word in combination

with an F word.

Example: To cut an inch thread of 11 threads per inch (25.4/11 8 2.309091)

•

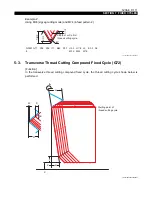

Feed Hold During Thread Cutting Cycle

This function is effective while an the Z (X) axis is moving in the G33 (G32) mode. Pressing the

SLIDE HOLD pushbutton during the thread cutting cycle stops axis movement immediately,

breaking the thread being cut and damaging the workpiece. This function is provided to prevent

such trouble.

Activate this function to check the dimensions and shape of the threads being cut and also to

check the tip point of the thread cutting tool.

1) The same restrictions apply in G01 linear interpolation mode operation.

2) The maximum feedrates vary according to the machine specifications.

G34

X

Z

F25.4 J11

(1 mm unit system)

G34

X

Z

F230.9091

(10

µ

m unit system)

G34

X

Z

F2.309091

(1 mm unit system)

G34

X

Z

F2309.091

(1

µ

m unit system)

Spindle speed N = 100

×

10

3

10

π

= 3183 (rev/min)

Feedrate N

×

P = 3183

×

1.5 = 4775 (mm/min)

The incomplete thread length can be calculated as follows:

δ

1 =

δ

2 = 0.53

×

10

-3

×

4775 = 2.53 (mm)

Therefore,

δ

1 and

δ

2 should be 2.53 (mm) or longer.

where,

N: spindle speed

P: lead

Programmable thread lead

0.001 to 1000.000 mm

Spindle speed:

X-axis : Max. feedrate of X-axis

> N

×

P

Z-axis : Max. feedrate of Z-axis

> N

×

P