5238-E P-176

SECTION 8 LATHE AUTO-PROGRAMMING FUNCTION (LAP)

5.

Bar Turning Cycle (G85)

[Program format]

LE33013R0301000050001

[Function]

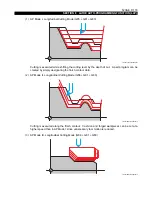

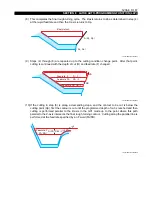

With the commands above, the control starts searching for the contour definition program beginning

with the sequence name NAT01. After assigning the parameter data of D, F, U, W and G84 to

NAT01, the control starts the bar turning cycle.

[Supplement]

•

Do not designate an S, T, or M code in the G85 block.

•

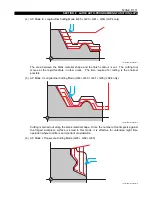

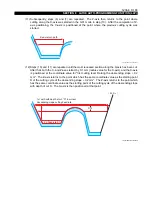

The D word is used to specify depth of cut in the rough turning cycle. When a G84 command

indicating change of cutting conditions is designated, the D word is effective up to the point

where the change is made, XA and ZA.

A D word must be always be designated in the G85 block, with a value greater than "0". Illegal

designation will cause an alarm.

•

The F word is used to specify the feedrate in a rough turning cycle. When a G84 command

indicating change of cutting conditions is designated, the F word is effective up to the point

where the change is made, XA and ZA.

•

If no F word is designated in the G85 block, the feedrate which was effective before the

execution of the G85 block is effective.

The F word must be positive. If not, an alarm occurs.

•

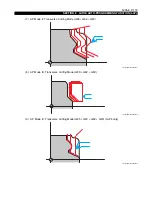

When a U and/or W word is not designated, U and/or W is assumed to be "0".

U and W words must be positive or zero. If not, an alarm occurs.

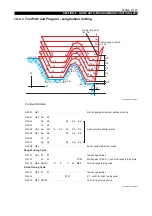

N0103

D

F

U

W

G84

Sequence number

G85

G code calling out bar turning cycle

To be designated right after sequence number (name).

NAT01

Sequence name in the first block of contour defining blocks

Enter either tab or space code.

Depth of cut in rough turning cycle

Feedrate in rough turning cycle

Stock removal in finish turning cycle,

X component

Stock removal in finish turning cycle,

Z component

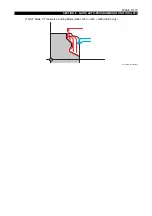

Change of rough

turning conditions