5238-E P-98

SECTION 7 FIXED CYCLES

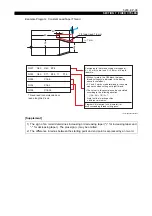

Example Program: Constant Lead Taper Thread

LE33013R0300900030003

[Supplement]

1) The sign of an I word determines increasing or decreasing taper ("+" for increasing taper and

"-" for decreasing taper). The plus sign (+) may be omitted.

2) The difference in radius between the starting point and end point is expressed by an I word.

N001

N002

N003

N004

N005

G00

G33

X40

X17

X16.5

X16.2

X16.05

Z96

Z54

17

F1.5

Positioning to the thread cutting starting point,

X = 40 mm (in dia.) and Z = 96 mm, at a rapid

feedrate.

Thread lead is commanded as a

lead along the Z-axis.

•

With an I word in the G33 block,the taper

thread cutting cycle indicated in the drawing

above is carried out.

•

X, Z and F words are determined in the same

manner as when cutting a straight thread.

•

The value I in this example can be calculated

according to the following equation:

[(96 - 54)

×

1/3]/2 = 7

Note that the I word specifies

a difference in radius.

Program X dimension (as a diameter) for

each succeeding thread cutting pass.

90

60

6

6

20

φ

30

φ

I = 7 mm

1/3 taper, lead 1.5 mm