- 6.2 -

Before Taking A Phenomenon As A Sign Of Failue

In this section gives you corrective measures against troubles in the case where no error message is

given on the LCD are described. Be sure to take the following measures before taking the trouble as

a sign of failure. If the measures fail to restore the device to the normal state, contact your local

MIMAKI distributor or MIMAKI office.

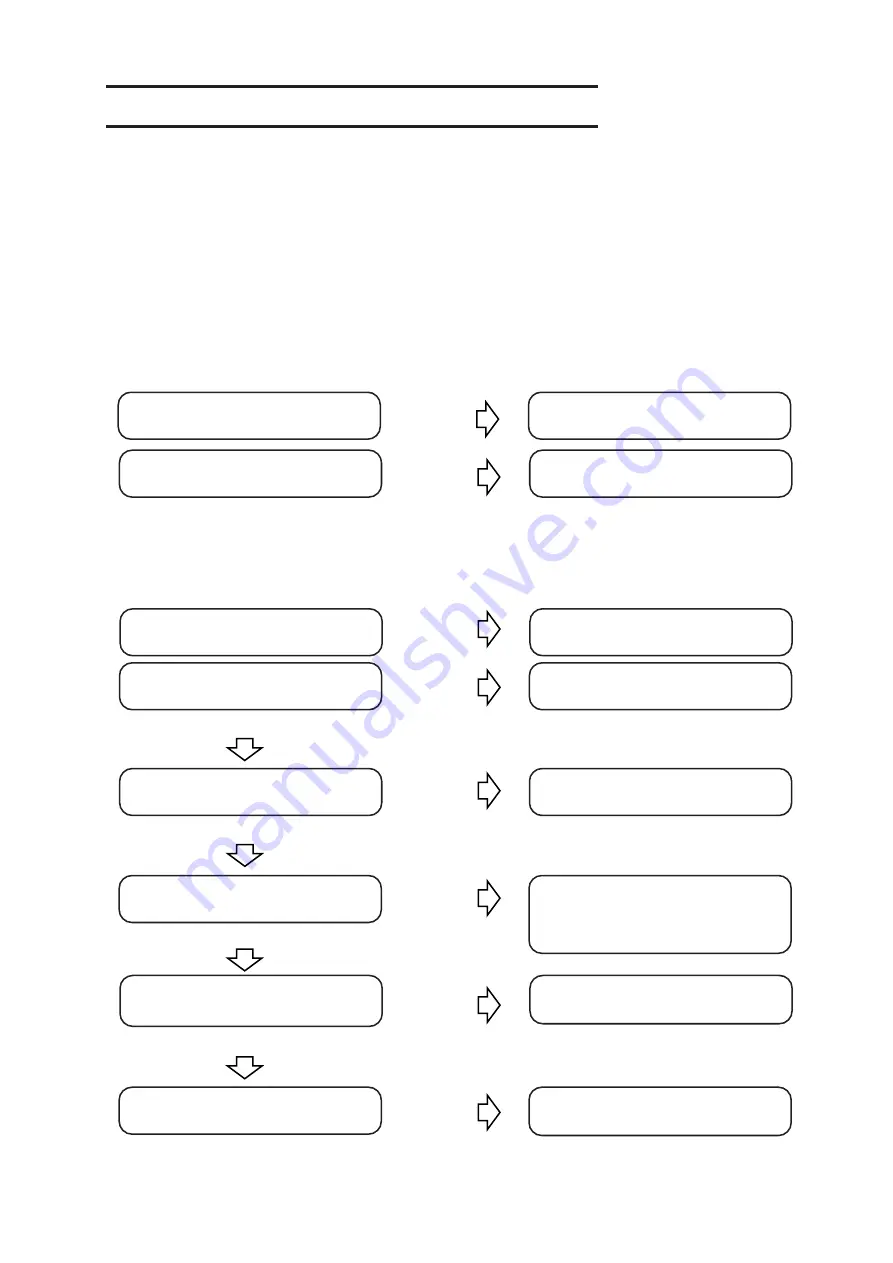

The device cannot be energized

The main cause of problems with turning on the power is failure to connect the power cable to the

computer properly. Check that it is connected properly again.

The device cannot perform printing

This occurs when the data is not being transmitted to the device properly. It can also occur when any

of the device functions fails or the fabric has been set improperly.

Has the power cable been connected

to the device and the receptacle?

No

Is the correct interface cable used?

Has the interface cable been

securely connected in position?

Is the message telling that ink has

run out shown on the display?

Is the feeding tension bar raised ?

Is fabric shifted largely from the

peeling sensor ?

Is the take-up tension bar raised ?

No

No

Yes

No

No

Yes

Use an IEEE1394 or IEEE1284 inter-

face cable. Refer to Page 1.18.

Securely connect the interface cable

in position. Refer to Page 1.18.

Replace the ink cartridge with a new

one. Refer to Page 2.53.

Check whether the END of fabric is

reached or the feeding rotation is

reverse.

Set the fabric again and then per-

formed the fabric detection.

If the take-up device is set to

“MANUAL”, set it to “AUTO.”

No

No

Yes

Yes

Contact your local distributor to call

for service.

Has the power cable been connected

to the device and the receptacle?

Yes

Connect the power cable.

Summary of Contents for Textile Jet Tx3-1600

Page 2: ......

Page 54: ...1 34...

Page 142: ...3 34...

Page 170: ...4 28...

Page 192: ...5 22...

Page 206: ...6 14...

Page 217: ......

Page 218: ...PrintedinJapan MIMAKI ENGINEERING Co Ltd 2005 EA TM...