Setup & Operation 3. Environment and Installation

C8 Rev.13

31

3.2 Unpacking, Transportation, and Relocation

Using a cart or similar equipment, transport the Manipulator in the same conditions as it was

delivered. Observe the following when unpacking the Manipulator.

The installation shall be made by qualified installation personnel and should conform to all

national and local codes

.

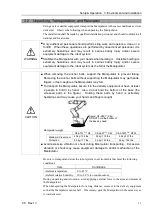

WARNING

■

Only authorized personnel should perform sling work and operate a crane or a

forklift. When these operations are performed by unauthorized personnel, it is

extremely hazardous and may result in serious bodily injury and/or severe

equipment damage to the robot system.

■

Stabilize the Manipulator with your hands when hoisting it. Unstable hoisting is

extremely hazardous and may result in serious bodily injury and/or severe

equipment damage to the robot system as the fall of the Manipulator.

CAUTION

■

When removing the anchor bolts, support the Manipulator to prevent falling.

Removing the anchor bolts without supporting the Manipulator may get hands,

fingers, or feet caught as the Manipulator may fall.

■

To transport the Manipulator, secure it to the delivery equipment or have at least

2 people to hold it by hand. Also, do not hold the bottom of the base (the

screened parts in the figure). Holding these parts by hand is extremely

hazardous and may cause your hands and fingers caught.

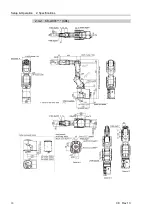

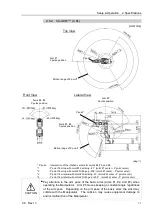

Figure: C8-A901* (C8L)

DO NOT hold the bottom of

the base by hand.

Manipulator weight

C8-A701***: C8

C8-A901***: C8L

C8-A1401***: C8XL

Standard, Cleanroom

49 kg: 108 lbs.

52 kg: 115 lbs.

62 kg:137 lbs.

Protection

53 kg: 117 lbs.

56 kg: 123 lbs.

66 kg: 146 lbs.

■

Avoid excessive vibration or shock during Manipulator transporting. Excessive

vibration or shock may cause equipment damage to and/or malfunction of the

Manipulator.

Be sure to transport and store the robot system in environments that meet the following

conditions:

Item

Conditions

Ambient temperature

0 to 45

°

C

Ambient relative humidity 10 to

80 % (no condensation)

During unpacking and relocation, avoid applying external force to the arms and motors of

the Manipulator.

When transporting the Manipulator for a long distance, secure it to the delivery equipment

so that the Manipulator cannot fall. If necessary, pack the Manipulator in the same way as

it was delivered.

Summary of Contents for C8 Series

Page 1: ...Rev 13 EM208R4413F 6 Axis Robots C8 series MANIPULATOR MANUAL ...

Page 2: ...Manipulator manual C8 series Rev 13 ...

Page 8: ...vi C8 Rev 13 ...

Page 14: ...Table of Contents xii C8 Rev 13 ...

Page 16: ......

Page 31: ...Setup Operation 2 Specifications C8 Rev 13 17 2 4 Outer Dimensions Unit mm 2 4 1 C8 A701 C8 ...

Page 32: ...Setup Operation 2 Specifications 18 C8 Rev 13 2 4 2 C8 A901 C8L ...

Page 33: ...Setup Operation 2 Specifications C8 Rev 13 19 2 4 3 C8 A1401 C8XL ...

Page 49: ...Setup Operation 3 Environment and Installation C8 Rev 13 35 C8 A901 C8L ...

Page 98: ......

Page 183: ...Maintenance 4 Cable Unit C8 Rev 13 169 4 2 Connector Pin Assignment 4 2 1 Signal Cable ...

Page 184: ...Maintenance 4 Cable Unit 170 C8 Rev 13 ...

Page 185: ...Maintenance 4 Cable Unit C8 Rev 13 171 ...

Page 186: ...Maintenance 4 Cable Unit 172 C8 Rev 13 4 2 2 Power Cable C8 A701 C8 C8 A901 C8L ...

Page 187: ...Maintenance 4 Cable Unit C8 Rev 13 173 C8 A1401 C8XL ...

Page 188: ...Maintenance 4 Cable Unit 174 C8 Rev 13 C8 A701 C8 C8 A901 C8L C8 A1401 C8XL ...