Setup & Operation 1. Safety

C8 Rev.13

7

1.4 Emergency Stop

If the Manipulator moves abnormally during operation, immediately press the Emergency

Stop switch. Pressing the Emergency Stop switch immediately changes the Manipulator

to deceleration motion and stops it at the maximum deceleration speed.

However, avoid pressing the Emergency Stop switch unnecessarily while the Manipulator

is running normally. Otherwise, the Manipulator may hit the peripheral equipment since

the operating trajectory until the robot system stops is different from that in normal operation.

Do not press the Emergency Stop switch unnecessarily while the Manipulator is operating.

Pressing the switch during operation makes the brakes work. This will shorten the life of

the brakes due to the worn friction plates.

Normal brake life cycle: About 2 years (when the brakes are used 100 times/day)

Also, the Emergency Stop during operation applies impact on the reduction gear unit, and it

may result in the short life of the reduction gear unit.

To place the robot system in emergency mode during normal operation, press the Emergency

Stop switch while the Manipulator is not moving.

Refer to the Robot Controller manual for instructions on how to wire the Emergency Stop

switch circuit.

Do not turn OFF the Controller while the Manipulator is operating.

If you attempt to stop the Manipulator in emergency situations such as “Safeguard Open”,

make sure to stop the Manipulator using the Emergency Stop switch of the Controller.

If the Manipulator is stopped by turning OFF the Controller while it is operating, the

following problems may occur.

Reduction of the life and damage of the reduction gear unit

Position gap at the joints

In addition, if the Controller was forced to be turned OFF by blackouts and the like while

the Manipulator is operating, make sure to check the following points after power restoration.

Whether or not the reduction gear is damaged

Whether or not the joints are in their proper positions

If there is a position gap, perform calibration by referring to the

Maintenance 16.

Calibration

in this manual.

Before using the Emergency Stop switch, be aware of the followings.

-

The Emergency Stop (E-STOP) switch should be used to stop the Manipulator only in

case of emergencies.

-

To stop the Manipulator operating the program except in emergency, use Pause (halt)

or STOP (program stop) commands.

Pause and STOP commands do not turn OFF the motors. Therefore, the brake does

not function.

-

For the Safeguard system, do not use the circuit for E-STOP.

Summary of Contents for C8 Series

Page 1: ...Rev 13 EM208R4413F 6 Axis Robots C8 series MANIPULATOR MANUAL ...

Page 2: ...Manipulator manual C8 series Rev 13 ...

Page 8: ...vi C8 Rev 13 ...

Page 14: ...Table of Contents xii C8 Rev 13 ...

Page 16: ......

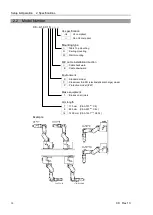

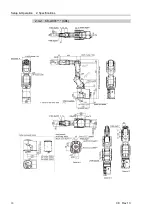

Page 31: ...Setup Operation 2 Specifications C8 Rev 13 17 2 4 Outer Dimensions Unit mm 2 4 1 C8 A701 C8 ...

Page 32: ...Setup Operation 2 Specifications 18 C8 Rev 13 2 4 2 C8 A901 C8L ...

Page 33: ...Setup Operation 2 Specifications C8 Rev 13 19 2 4 3 C8 A1401 C8XL ...

Page 49: ...Setup Operation 3 Environment and Installation C8 Rev 13 35 C8 A901 C8L ...

Page 98: ......

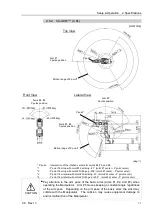

Page 183: ...Maintenance 4 Cable Unit C8 Rev 13 169 4 2 Connector Pin Assignment 4 2 1 Signal Cable ...

Page 184: ...Maintenance 4 Cable Unit 170 C8 Rev 13 ...

Page 185: ...Maintenance 4 Cable Unit C8 Rev 13 171 ...

Page 186: ...Maintenance 4 Cable Unit 172 C8 Rev 13 4 2 2 Power Cable C8 A701 C8 C8 A901 C8L ...

Page 187: ...Maintenance 4 Cable Unit C8 Rev 13 173 C8 A1401 C8XL ...

Page 188: ...Maintenance 4 Cable Unit 174 C8 Rev 13 C8 A701 C8 C8 A901 C8L C8 A1401 C8XL ...