Maintenance 4. Cable Unit

134

C12 Rev.3

61.

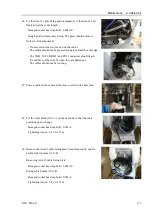

Install the plate for preventing cable interference.

Hexagon socket head cap bolts: 2-M3

×

6

Tightening torque: 2.0

±

0.1 N·m

62.

Install the Joint #1 motor unit.

For details, refer to

Maintenance: 5.1.1 Joint #1 - Replacing the Motor (M/C Cable Backward),

Installation steps (1) to (4).

63.

Push out the following cables upward through the opening of the

base.

D-sub cable

Ground wire

RJ45 connector

F-sensor connector

64.

Install the brake power supply to the plate.

The cables should be located in the direction as shown in the photo.

(See the photo.)

Cross recessed head screws with washer: 2-M3

×

6

Tightening torque: 0.45

±

0.1 N·m

65.

Install the ground wire terminals to the plate.

Cross recessed head screws with washer:

9-M4

×

8, 2-M3

×

6

Tightening torque : 0.9

±

0.1N·m (M4

×

8)

0.45

±

0.1 N·m (M3

×

6)

The installation positions of the D-sub cable ground terminals are predetermined. Make sure to install

them to the two screw holes on the backside of the Manipulator (indicated with arrows in the photo).

NOTE

Summary of Contents for C12 Series

Page 1: ...Rev 3 EM204R4255F 6 Axis Robots C12 series MANIPULATOR MANUAL ...

Page 2: ...Manipulator manual C12 series Rev 3 ...

Page 8: ...vi C12 Rev 3 ...

Page 14: ...Table of Contents xii C12 Rev 3 ...

Page 16: ......

Page 30: ...Setup Operation 2 Specifications 16 C12 Rev 3 2 4 Outer Dimensions Unit mm ...

Page 84: ......

Page 155: ...Maintenance 4 Cable Unit C12 Rev 3 141 4 2 Connector Pin Assignment 4 2 1 Signal Cable ...

Page 156: ...Maintenance 4 Cable Unit 142 C12 Rev 3 ...

Page 157: ...Maintenance 4 Cable Unit C12 Rev 3 143 ...

Page 158: ...Maintenance 4 Cable Unit 144 C12 Rev 3 4 2 2 Power Cable ...