Maintenance 4. Cable Unit

122

C12 Rev.3

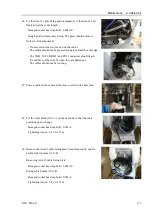

As shown in the photo, disconnect the Ethernet cable and air tube

(blue) at one side of the Arm #4.

Disconnect the remaining cables at the other side.

Align the marked positions and the position on the Arm #4

indicated with the arrow in the photo.

9.

Install the cable fixing plate to the Arm #4.

Hexagon socket head cap bolts: 2-M4

×

10

Tightening torque: 4.0

±

0.2 N·m

10.

Use a cable bracket (C4) to fix the cables.

Hexagon socket head cap bolts: 2-M3

×

6

Tightening torque: 2.4

±

0.1 N·m

Place the silicone tube to the position where it is fixed with a cable bracket.

Use a cable bracket to fix the silicone tube.

11.

Install the D-sub connector to the D-sub attachment of the Arm #4.

D-sub connector fixing plate is provided.

Hold the D-sub connector between the D-sub attachment of the Arm

#4 and the D sub connector fixing plate, and fix them with the locking

screws removed in step 3 above.

(The nuts and washers are not used.)

NOTE

Summary of Contents for C12 Series

Page 1: ...Rev 3 EM204R4255F 6 Axis Robots C12 series MANIPULATOR MANUAL ...

Page 2: ...Manipulator manual C12 series Rev 3 ...

Page 8: ...vi C12 Rev 3 ...

Page 14: ...Table of Contents xii C12 Rev 3 ...

Page 16: ......

Page 30: ...Setup Operation 2 Specifications 16 C12 Rev 3 2 4 Outer Dimensions Unit mm ...

Page 84: ......

Page 155: ...Maintenance 4 Cable Unit C12 Rev 3 141 4 2 Connector Pin Assignment 4 2 1 Signal Cable ...

Page 156: ...Maintenance 4 Cable Unit 142 C12 Rev 3 ...

Page 157: ...Maintenance 4 Cable Unit C12 Rev 3 143 ...

Page 158: ...Maintenance 4 Cable Unit 144 C12 Rev 3 4 2 2 Power Cable ...