Maintenance 4. Cable Unit

128

C12 Rev.3

32.

Install the Joint #3 motor unit.

For details, refer to

Maintenance: 7.1 Joint #3 - Replacing the Motor,

Installation steps (4) and (8).

33.

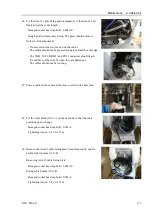

Fix the two ground wire terminals to the Arm #2.

Green: Right side

Green/yellow: Left side

Cross recessed head screws with washer: 2-M4

×

8

Tightening torque: 0.9

±

0.1 N·m

34.

Use the cable protection spring to bind cables at the Arm #2 cable

fixing plate.

Type of wire tie: AB100

Number of wire ties: 4

Be careful of the orientation of the Arm #2 cable fixing plate.

The side with two U-shaped grooves should be placed down.

35.

Use cable brackets (C2) to fix the cables to the Arm #2 cable fixing

plate temporarily.

Place the silicone tube to the position where it is fixed with a cable

bracket.

Use a cable bracket to fix the silicone tube temporarily.

Hexagon socket head cap bolts: 2-M3

×

6

Rough guide of temporary fixing:

The cables can be pushed up even after fixing the cables.

36.

Install the Arm #2 cable fixing plate to the Arm #2.

After fitting the two U-shaped grooves to the fixing bolts, tighten the

bolts.

Hexagon socket head cap bolts: 2-M4

×

10

Tightening torque: 4.0

±

0.2 N·m

Summary of Contents for C12 Series

Page 1: ...Rev 3 EM204R4255F 6 Axis Robots C12 series MANIPULATOR MANUAL ...

Page 2: ...Manipulator manual C12 series Rev 3 ...

Page 8: ...vi C12 Rev 3 ...

Page 14: ...Table of Contents xii C12 Rev 3 ...

Page 16: ......

Page 30: ...Setup Operation 2 Specifications 16 C12 Rev 3 2 4 Outer Dimensions Unit mm ...

Page 84: ......

Page 155: ...Maintenance 4 Cable Unit C12 Rev 3 141 4 2 Connector Pin Assignment 4 2 1 Signal Cable ...

Page 156: ...Maintenance 4 Cable Unit 142 C12 Rev 3 ...

Page 157: ...Maintenance 4 Cable Unit C12 Rev 3 143 ...

Page 158: ...Maintenance 4 Cable Unit 144 C12 Rev 3 4 2 2 Power Cable ...