86

Elmark Automatyka S.A.

ul. Niemcewicza 76, 05-075 Warszawa, tel. (+48) 22 773 79 37; [email protected]; www.elmark.com.pl

NIP: 5252072585; KRS: 0000803828, Sąd Rejonowy dla M-St. Warszawy, XIV Wydział Gosp. KRS; Kapitał Zakładowy 525.000 zł, w pełni opłacony

Chapter 5 Fault checking and ruled out

5.1

Fault alarm and countermeasures

ED2000 inverter with a total of 28 warning information and the protection function, once the failure, protection function, inverter

to stop output, inverter fault relay contact action, and in the inverter fault code shown on the display panel. the user can check

himself according to the tips before seeking service, analyze the cause of the problem, find out the solution. If belong to the dotted

line frame stated reason, please seek service, with your purchased inverter agents or direct contact with our company.

21 warning information OUOC is overcurrent or overvoltage signals for hardware, in most cases the hardware overvoltage fault

cause OUOC alarm.

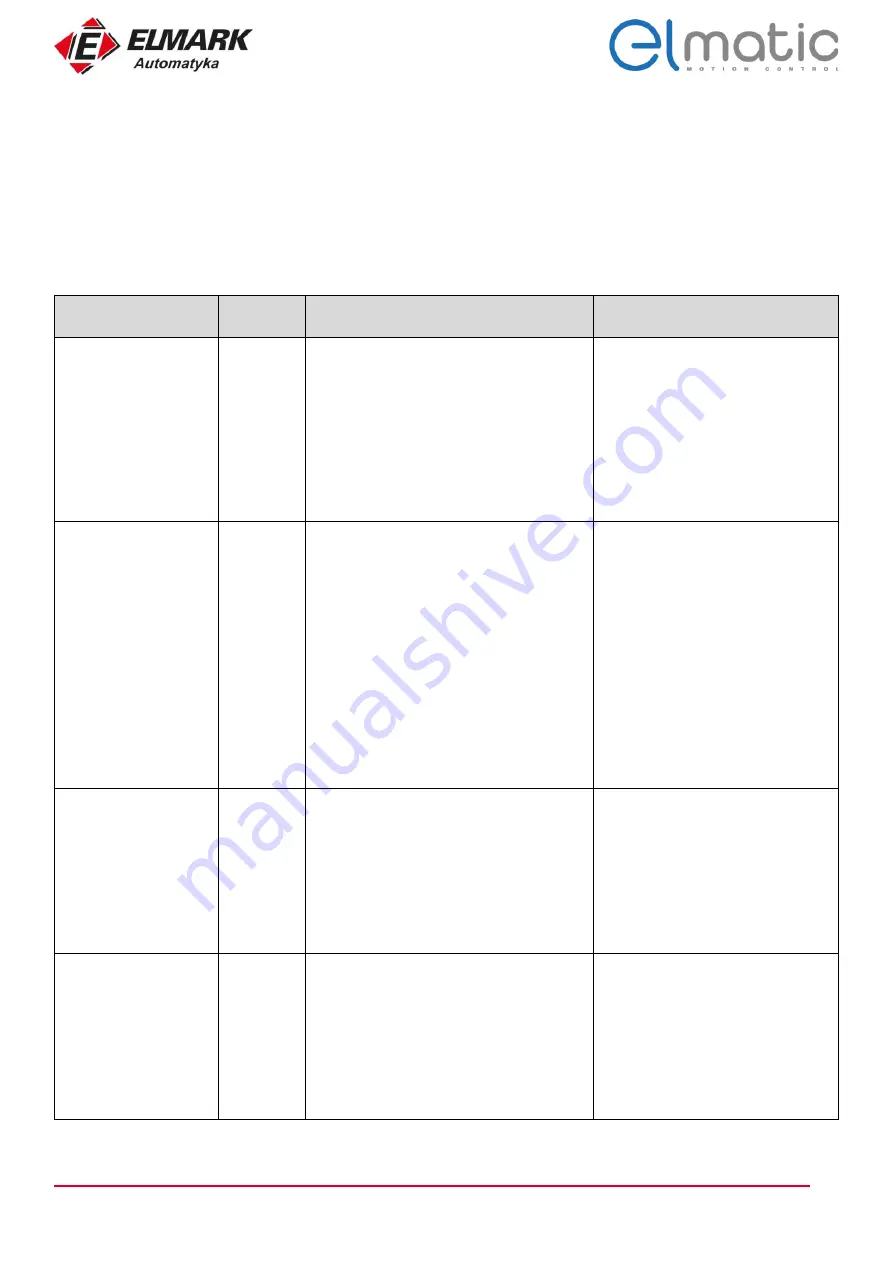

Fault Name

Display of

Panel

Possible Causes

Solutions

Inverter unit protection

OC

1: The output circuit is grounded or short

circuited.

2: The connecting cable of the motor is too

long.

3: The module overheats.

4: The internal connections become loose.

5:The main control board is faulty.

6: The drive board is faulty.

7: The inverter module is faulty

1: Eliminate external faults.

2: Install a reactor or an output filler.

3: Check the air filler and the cooling

fan.

4: Connect all cables Properly.

5,6,7:Looking for technical support

Overcurrent during

acceleration

OC1

1 : The output circuit is grounded or short

circuited.

2: Motor auto-tuning is not Performed.

3: The acceleration time is too Short.

4: Manual torque boost or V/F curve is not

appropriate.

5: The voltage is too low.

6: The startup operation is performed on the

rotating motor.

7: A sudden load is added

During Acceleration.

8: The AC drive model is of too small power

class.

1: Eliminate external faults.

2: Perform the motor

auto-tuning.

3: Increase the acceleration time.

4: Adjust the manual torque boost or

V/F curve.

5: Adjust the voltage to normal range.

6: Select rotational speed tracking

restart or start the motor after it stops.

7: Remove the added load.

8: Select an AC drive of

higher power class.

Overcurrent during

acceleration

OC2

1: The output circuit is grounded or short

circuited.

2: Motor auto-tuning is not performed.

3: The deceleration time is too Short.

4:The voltage is too low.

5: A sudden load is added during Deceleration.

6: The braking unit and braking resistor are not

installed.

1: Eliminate external faults.

2: Perform the motor auto- tuning.

3: Increase the deceleration time.

4: Adjust the voltage to normal range.

5: Remove the added load.

6: Install the braking unit and braking

resistor.

Overcurrent during

acceleration

OC2

1: The output circuit is grounded or short

circuited.

2: Motor auto-tuning is not performed.

3: The deceleration time is too Short.

4:The voltage is too low.

5: A sudden load is added during Deceleration.

6: The braking unit and braking resistor are not

installed.

1: Eliminate external faults.

2: Perform the motor auto- tuning.

3: Increase the deceleration time.

4: Adjust the voltage to normal range.

5: Remove the added load.

6: Install the braking unit and braking

resistor.

Summary of Contents for elmatic ED2000

Page 1: ......