APPENDIX

Page 513

To check the intake air ducts and air cleaner

canister, carefully wipe the inside surfaces with a

rag held by gloved hand. The rag will snag on

pieces that may be imbedded in the inner

surfaces of the ducts and canister. The glove and

rag will protect the hand from being scratched or

cut on any imbedded objects.

Cleaning the Turbocharger Oil

Supply Line, Changing the Engine

Oil and Pre-Lubricating the

Turbocharger Following a Failure

A turbocharger failure can result in debris

contaminating the turbocharger oil supply line. It

is EXTREMELY IMPORTANT to remove, flush

and thoroughly clean the line prior to installing the

replacement turbocharger. Failure to do so can

result in debris from the oil line entering the

replacement turbocharger, causing damage to

the bearings and eventual failure of the

replacement turbocharger.

1. Drain the engine oil.

2. Remove the turbocharger oil supply line and

inspect for kinks or other types of damage.

Replace the line as required. If the oil line is

undamaged, it can be reused.

Stainless steel braided lines can be crimped shut

if not handled or installed correctly. If the steel

braid has been kinked, it pinches the inner tube,

and even if the steel braid is straightened, the

inner tube will remain pinched. Caution must be

used not to bend or twist the steel braided line to

the point where it becomes kinked. If the line has

been kinked, it must be replaced to eliminate

turbocharger damage resulting from restricted oil

flow.

If the oil line is being reused, it must be

flushed with a clean, suitable,

non-flammable solvent. Allow solvent to run

through the line to flush any debris from the

inside, and then blow the line dry with clean

shop air.

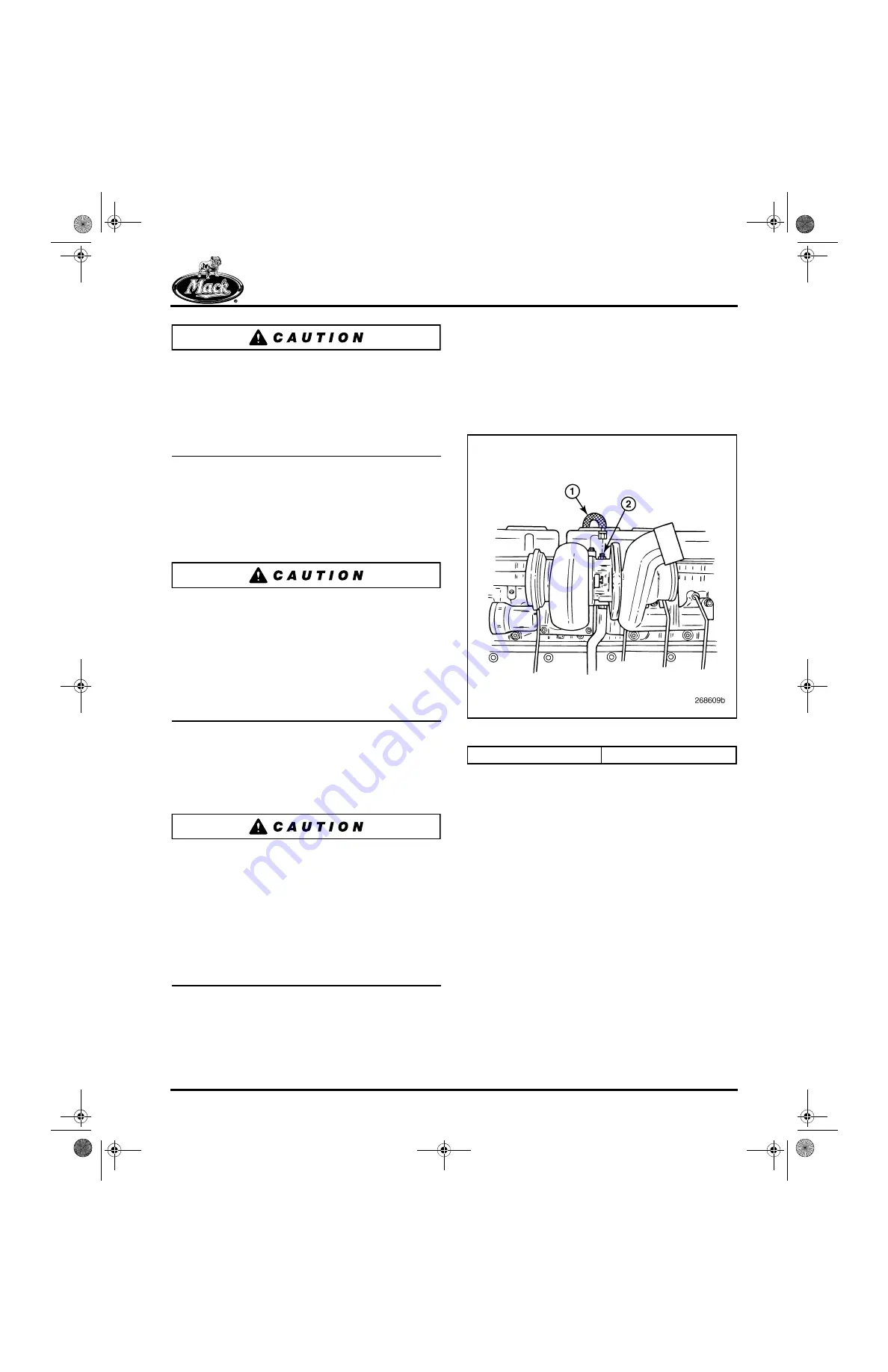

3. Mount the turbocharger on the exhaust

manifold, install the oil drain tube and

connect the exhaust pipe. Do not connect

the oil supply line or the inlet air duct to the

turbocharger.

4. Pour clean engine oil into the oil inlet port at

the top of the turbocharger until overflowing.

590

Figure 590 — Turbocharger Oil Inlet Port

5. Spin the compressor wheel by hand several

revolutions and wiggle the shaft back and

forth. This will ensure that oil is distributed

over all bearing surfaces.

6. Install the inlet air duct to the turbocharger,

but do not connect the oil supply line at this

time.

7. Change the spin-on oil filters and the

centrifugal oil filter as outlined in the

Maintenance and Lubrication Manual,

TS494. Be sure to prefill each new spin-on

filter with 2 quarts of new engine oil.

8. Fill the engine crankcase with the proper

specification and grade of engine oil (refer to

the

Maintenance and Lubrication Manual,

TS494, for current engine oil specifications).

1. Oil Inlet Line

2. Oil Inlet Port

appendix.fm Page 513 Tuesday, July 11, 2006 11:18 AM

Содержание ASET AC

Страница 6: ...TABLE OF CONTENTS Page iii TABLE OF CONTENTS 5 111 bk Page iii Monday July 10 2006 2 26 PM...

Страница 14: ...INTRODUCTION Page 1 INTRODUCTION 5 111 bk Page 1 Monday July 10 2006 2 26 PM...

Страница 23: ...Page 10 NOTES 5 111 bk Page 10 Monday July 10 2006 2 26 PM...

Страница 24: ...VISUAL IDENTIFICATION Page 11 VISUAL IDENTIFICATION 5 111 bk Page 11 Monday July 10 2006 2 26 PM...

Страница 28: ...DESCRIPTION AND OPERATION Page 15 DESCRIPTION AND OPERATION 5 111 bk Page 15 Monday July 10 2006 2 26 PM...

Страница 96: ...COMPONENT LOCATOR Page 83 COMPONENT LOCATOR 5 111 bk Page 83 Monday July 10 2006 2 26 PM...

Страница 99: ...Page 86 NOTES 5 111 bk Page 86 Monday July 10 2006 2 26 PM...

Страница 100: ...TROUBLESHOOTING Page 87 TROUBLESHOOTING 5 111 bk Page 87 Monday July 10 2006 2 26 PM...

Страница 140: ...MAINTENANCE Page 127 MAINTENANCE 5 111 bk Page 127 Monday July 10 2006 2 26 PM...

Страница 153: ...Page 140 NOTES 5 111 bk Page 140 Monday July 10 2006 2 26 PM...

Страница 154: ...REPAIR INSTRUCTIONS PART 1 Page 141 REPAIR INSTRUCTIONS PART 1 5 111 bk Page 141 Monday July 10 2006 2 26 PM...

Страница 383: ...Page 370 NOTES 5 111 bk Page 370 Monday July 10 2006 2 26 PM...

Страница 384: ...REPAIR INSTRUCTIONS PART 2 Page 371 REPAIR INSTRUCTIONS PART 2 5 111 bk Page 371 Monday July 10 2006 2 26 PM...

Страница 454: ...REPAIR INSTRUCTIONS PART 3 Page 441 REPAIR INSTRUCTIONS PART 3 5 111 bk Page 441 Monday July 10 2006 2 26 PM...

Страница 479: ...Page 466 NOTES 5 111 bk Page 466 Monday July 10 2006 2 26 PM...

Страница 480: ...SPECIFICATIONS Page 467 SPECIFICATIONS 5 111 bk Page 467 Monday July 10 2006 2 26 PM...

Страница 505: ...Page 492 NOTES 5 111 bk Page 492 Monday July 10 2006 2 26 PM...

Страница 506: ...SCHEMATIC ROUTING DIAGRAMS Page 493 SCHEMATIC ROUTING DIAGRAMS 5 111 bk Page 493 Monday July 10 2006 2 26 PM...

Страница 513: ...Page 500 NOTES 5 111 bk Page 500 Monday July 10 2006 2 26 PM...

Страница 514: ...SPECIAL TOOLS EQUIPMENT Page 501 SPECIAL TOOLS EQUIPMENT 5 111 bk Page 501 Monday July 10 2006 2 26 PM...

Страница 519: ...Page 506 NOTES 5 111 bk Page 506 Monday July 10 2006 2 26 PM...

Страница 520: ...APPENDIX Page 507 APPENDIX 5 111 bk Page 507 Monday July 10 2006 2 26 PM...

Страница 528: ...INDEX Page 515 INDEX Index fm Page 515 Monday July 10 2006 2 48 PM...

Страница 535: ...Page 522 NOTES Index fm Page 522 Monday July 10 2006 2 48 PM...