Page 310

REPAIR INSTRUCTIONS, PART 1

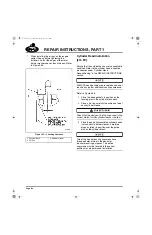

2. Install the shaft through the rear of the

auxiliary shaft housing. Use care when

aligning the shaft to avoid damage to the

rear bearing.

Refer to Figure 357.

3. Install the thrust washer and secure it in

position with the patch-lock capscrews and

hardened washers.

4. Tighten the thrust washer retaining

patch-lock capscrews to the specified

torque, 15 lb-ft (20 N

폷

m), using torque

wrench J 24406, or equivalent.

5. Install the auxiliary shaft gear on the shaft

splines.

The auxiliary shaft and nut threads must be clean

and dry before assembly. Clean the threads

thoroughly with Brakleen

®

or electrical contact

cleaner. If reusing the old nut, apply Loctite

®

271

or 277 to the threads and install the nut. If using a

new nut from the MACK Parts System, it is not

necessary to apply Loctite

®

as the nut threads

are coated with a pre-applied thread locker.

6. Install the auxiliary shaft nut and tighten to

the specified torque, 300 lb-ft (405 N

폷

m),

using torque wrench J 23775-01, or

equivalent.

Whether using a new or revised nut, it is critical

that the ground face of the nut (if applicable) be

installed toward the gear. Any identifications on

the nut face must be installed away from the

gear.

357

Figure 357 — Auxiliary Shaft Gear Installation

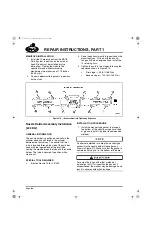

Oil Pump Installation

[219 MU]

Make sure that the oil pump is in satisfactory

condition as covered under “Lubrication System

Components Bench Procedures” in the REPAIR

INSTRUCTIONS section.

Because of differences in the gear set helixes of

current and earlier design engines, it is important

that the correct component/parts are installed.

앫

An improper drive gear on the oil pump will

prevent oil pump installation, assuming a

correct gear is on the auxiliary shaft.

앫

If an oil pump and an auxiliary shaft

assembly were replaced, two improper

gears could be installed, and engine failure

would result.

앫

In replacing any of these critical parts,

always refer to part number information in

the MACK Parts System to ensure the

correct component/part is being used.

1. Place the oil pump in position on the cylinder

block. Refer to Figure 358.

2. Apply Loctite

®

271 to the threads of the

pump mounting capscrews and install them.

Tighten the mounting capscrews to the

specified torque, 40 lb-ft (55 N

폷

m), using

torque wrench J 24407, or equivalent.

1. Nut

2. Auxiliary Shaft Gear

3. Capscrew

4. Thrust Washer

5. Shaft Splines

5-111.bk Page 310 Monday, July 10, 2006 2:26 PM

Содержание ASET AC

Страница 6: ...TABLE OF CONTENTS Page iii TABLE OF CONTENTS 5 111 bk Page iii Monday July 10 2006 2 26 PM...

Страница 14: ...INTRODUCTION Page 1 INTRODUCTION 5 111 bk Page 1 Monday July 10 2006 2 26 PM...

Страница 23: ...Page 10 NOTES 5 111 bk Page 10 Monday July 10 2006 2 26 PM...

Страница 24: ...VISUAL IDENTIFICATION Page 11 VISUAL IDENTIFICATION 5 111 bk Page 11 Monday July 10 2006 2 26 PM...

Страница 28: ...DESCRIPTION AND OPERATION Page 15 DESCRIPTION AND OPERATION 5 111 bk Page 15 Monday July 10 2006 2 26 PM...

Страница 96: ...COMPONENT LOCATOR Page 83 COMPONENT LOCATOR 5 111 bk Page 83 Monday July 10 2006 2 26 PM...

Страница 99: ...Page 86 NOTES 5 111 bk Page 86 Monday July 10 2006 2 26 PM...

Страница 100: ...TROUBLESHOOTING Page 87 TROUBLESHOOTING 5 111 bk Page 87 Monday July 10 2006 2 26 PM...

Страница 140: ...MAINTENANCE Page 127 MAINTENANCE 5 111 bk Page 127 Monday July 10 2006 2 26 PM...

Страница 153: ...Page 140 NOTES 5 111 bk Page 140 Monday July 10 2006 2 26 PM...

Страница 154: ...REPAIR INSTRUCTIONS PART 1 Page 141 REPAIR INSTRUCTIONS PART 1 5 111 bk Page 141 Monday July 10 2006 2 26 PM...

Страница 383: ...Page 370 NOTES 5 111 bk Page 370 Monday July 10 2006 2 26 PM...

Страница 384: ...REPAIR INSTRUCTIONS PART 2 Page 371 REPAIR INSTRUCTIONS PART 2 5 111 bk Page 371 Monday July 10 2006 2 26 PM...

Страница 454: ...REPAIR INSTRUCTIONS PART 3 Page 441 REPAIR INSTRUCTIONS PART 3 5 111 bk Page 441 Monday July 10 2006 2 26 PM...

Страница 479: ...Page 466 NOTES 5 111 bk Page 466 Monday July 10 2006 2 26 PM...

Страница 480: ...SPECIFICATIONS Page 467 SPECIFICATIONS 5 111 bk Page 467 Monday July 10 2006 2 26 PM...

Страница 505: ...Page 492 NOTES 5 111 bk Page 492 Monday July 10 2006 2 26 PM...

Страница 506: ...SCHEMATIC ROUTING DIAGRAMS Page 493 SCHEMATIC ROUTING DIAGRAMS 5 111 bk Page 493 Monday July 10 2006 2 26 PM...

Страница 513: ...Page 500 NOTES 5 111 bk Page 500 Monday July 10 2006 2 26 PM...

Страница 514: ...SPECIAL TOOLS EQUIPMENT Page 501 SPECIAL TOOLS EQUIPMENT 5 111 bk Page 501 Monday July 10 2006 2 26 PM...

Страница 519: ...Page 506 NOTES 5 111 bk Page 506 Monday July 10 2006 2 26 PM...

Страница 520: ...APPENDIX Page 507 APPENDIX 5 111 bk Page 507 Monday July 10 2006 2 26 PM...

Страница 528: ...INDEX Page 515 INDEX Index fm Page 515 Monday July 10 2006 2 48 PM...

Страница 535: ...Page 522 NOTES Index fm Page 522 Monday July 10 2006 2 48 PM...