Page 444

REPAIR INSTRUCTIONS, PART 3

Valve adjustments must be made in firing order

sequence (1-5-3-6-2-4) with the engine cold

(coolant temperature below 100

°

F [38

°

C]), and

not running. The flywheel should be rotated in its

normal direction of rotation to bring cylinder No. 1

up on the compression stroke and TDC (inlet and

exhaust valves closed). Continue to turn the

engine another 30 degrees to the mark on the

flywheel “Valves 1 & 6”. Adjust the valve yokes

and valves of the number one cylinder at this

position. Thereafter, continue to turn the engine

through its firing order sequence, adjusting the

valves at each “Valve” mark. The flywheel is

marked at 120-degree increments to indicate the

engine position at which the valves must be

adjusted. It is necessary to turn the engine

through two complete revolutions in order to

adjust the valves completely on an engine.

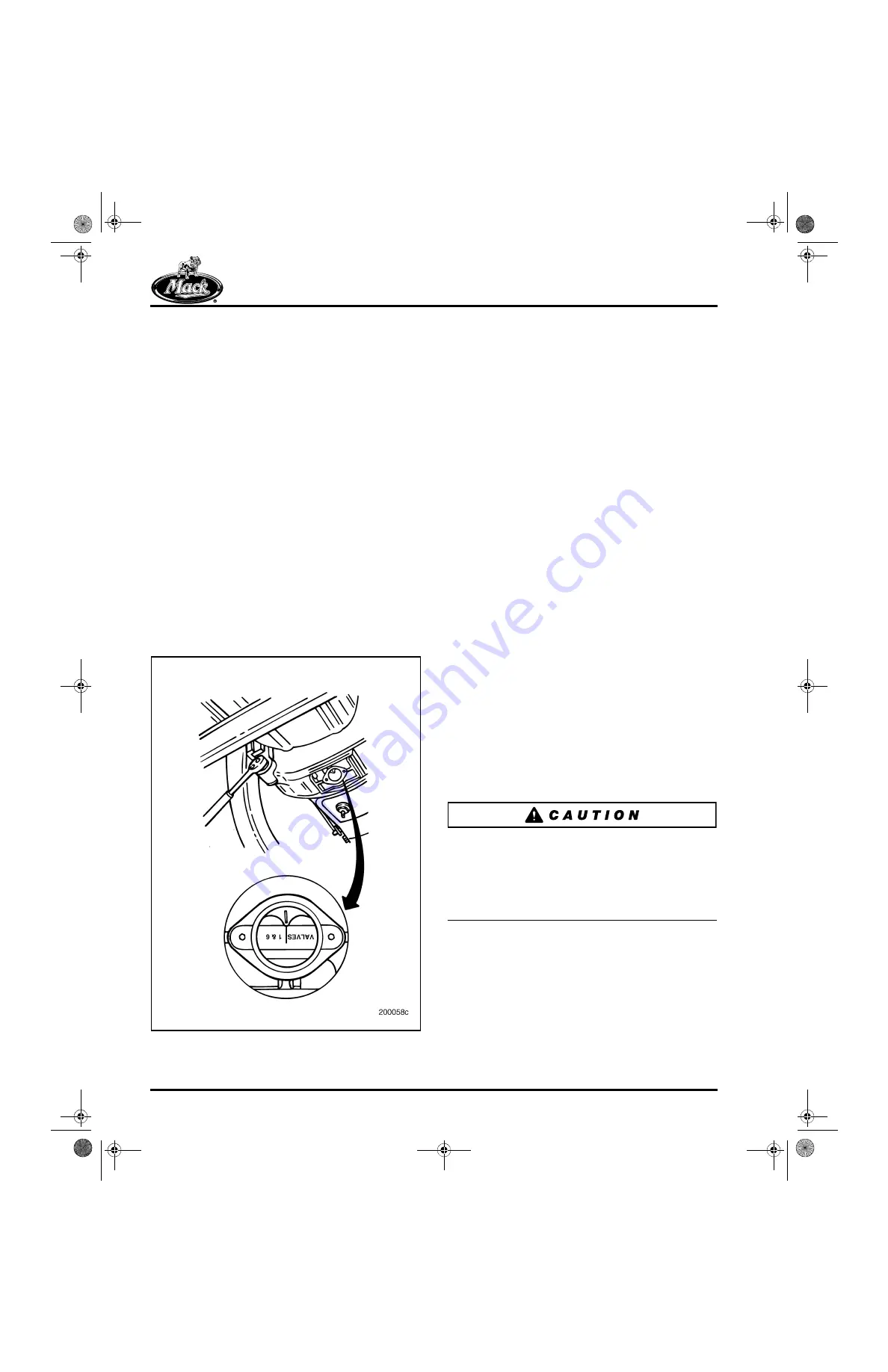

Access to the valve adjustment markings on the

flywheel is achieved by removing the cover from

the bottom of the flywheel housing. Tool

No. J 38587, which engages the flywheel through

an access hole in the flywheel housing, is

recommended to rotate the engine.

540

Figure 540 — Flywheel Valve Adjustment Markings

Valve adjustments are made in two stages. The

exhaust valve yoke is adjusted first, and then the

valve lash. Rotate the engine in the direction of

normal rotation until the valve adjustment

marking is aligned in the center of the access

window.

SPECIAL TOOLS REQUIRED

앫

Engine Barring Socket J 38587-A

앫

Torque Wrench J 24407

앫

T-Handle Torque Screwdriver J 29919

(Torque value preset to 6 lb-in)

앫

Hex Internal Bit, 5 mm

앫

Crow’s Foot Wrench, 8 mm 3/8-Inch Drive

앫

Crow’s Foot Wrench, 13 mm 3/8-Inch Drive

앫

Crow’s Foot Wrench, 14 mm 3/8-Inch Drive

앫

Adapter, 3/8-Inch to 1/4-Inch

앫

Drive Extension, 1/4-Inch

VALVE YOKE AND VALVE LASH

ADJUSTMENT FOR NON-BRAKE ENGINES

Valve Yoke Adjustment Procedure (Non-Brake

Engines)

Adjust the valve yokes at the exhaust valve

positions using the following procedure. As these

engines are equipped with the self-leveling

pinless valve yokes at the inlet positions, only the

exhaust valve yokes need to be adjusted.

Make sure that adjusting screws are retracted

upward in the rocker arms. If the adjusting screws

are not retracted and extend too far below the

rocker arm, the push rods can be bent and valve

lifter rollers damaged or broken when tightening

the rocker arm assembly brackets.

1. Using engine barring socket J 38587-A, or

equivalent, manually rotate engine in normal

rotation direction until pointer in flywheel

housing aligns with the valves 1 and 6 marks

on the flywheel and the No. 1 piston is at top

dead center on the compression stroke.

5-111.bk Page 444 Monday, July 10, 2006 2:26 PM

Содержание ASET AC

Страница 6: ...TABLE OF CONTENTS Page iii TABLE OF CONTENTS 5 111 bk Page iii Monday July 10 2006 2 26 PM...

Страница 14: ...INTRODUCTION Page 1 INTRODUCTION 5 111 bk Page 1 Monday July 10 2006 2 26 PM...

Страница 23: ...Page 10 NOTES 5 111 bk Page 10 Monday July 10 2006 2 26 PM...

Страница 24: ...VISUAL IDENTIFICATION Page 11 VISUAL IDENTIFICATION 5 111 bk Page 11 Monday July 10 2006 2 26 PM...

Страница 28: ...DESCRIPTION AND OPERATION Page 15 DESCRIPTION AND OPERATION 5 111 bk Page 15 Monday July 10 2006 2 26 PM...

Страница 96: ...COMPONENT LOCATOR Page 83 COMPONENT LOCATOR 5 111 bk Page 83 Monday July 10 2006 2 26 PM...

Страница 99: ...Page 86 NOTES 5 111 bk Page 86 Monday July 10 2006 2 26 PM...

Страница 100: ...TROUBLESHOOTING Page 87 TROUBLESHOOTING 5 111 bk Page 87 Monday July 10 2006 2 26 PM...

Страница 140: ...MAINTENANCE Page 127 MAINTENANCE 5 111 bk Page 127 Monday July 10 2006 2 26 PM...

Страница 153: ...Page 140 NOTES 5 111 bk Page 140 Monday July 10 2006 2 26 PM...

Страница 154: ...REPAIR INSTRUCTIONS PART 1 Page 141 REPAIR INSTRUCTIONS PART 1 5 111 bk Page 141 Monday July 10 2006 2 26 PM...

Страница 383: ...Page 370 NOTES 5 111 bk Page 370 Monday July 10 2006 2 26 PM...

Страница 384: ...REPAIR INSTRUCTIONS PART 2 Page 371 REPAIR INSTRUCTIONS PART 2 5 111 bk Page 371 Monday July 10 2006 2 26 PM...

Страница 454: ...REPAIR INSTRUCTIONS PART 3 Page 441 REPAIR INSTRUCTIONS PART 3 5 111 bk Page 441 Monday July 10 2006 2 26 PM...

Страница 479: ...Page 466 NOTES 5 111 bk Page 466 Monday July 10 2006 2 26 PM...

Страница 480: ...SPECIFICATIONS Page 467 SPECIFICATIONS 5 111 bk Page 467 Monday July 10 2006 2 26 PM...

Страница 505: ...Page 492 NOTES 5 111 bk Page 492 Monday July 10 2006 2 26 PM...

Страница 506: ...SCHEMATIC ROUTING DIAGRAMS Page 493 SCHEMATIC ROUTING DIAGRAMS 5 111 bk Page 493 Monday July 10 2006 2 26 PM...

Страница 513: ...Page 500 NOTES 5 111 bk Page 500 Monday July 10 2006 2 26 PM...

Страница 514: ...SPECIAL TOOLS EQUIPMENT Page 501 SPECIAL TOOLS EQUIPMENT 5 111 bk Page 501 Monday July 10 2006 2 26 PM...

Страница 519: ...Page 506 NOTES 5 111 bk Page 506 Monday July 10 2006 2 26 PM...

Страница 520: ...APPENDIX Page 507 APPENDIX 5 111 bk Page 507 Monday July 10 2006 2 26 PM...

Страница 528: ...INDEX Page 515 INDEX Index fm Page 515 Monday July 10 2006 2 48 PM...

Страница 535: ...Page 522 NOTES Index fm Page 522 Monday July 10 2006 2 48 PM...