REPAIR INSTRUCTIONS, PART 3

Page 463

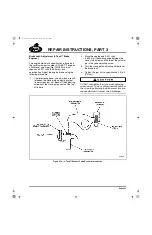

Usually there are various points on the engine

where a pressure line may be tapped into, but if

no other is apparent, the oil gauge line may be

disconnected and a pressure tank applied at that

point.

PRIMING THE LUBRICATION SYSTEM

1. Fill the engine crankcase to the specified

capacity with the recommended

MACK-specified EO-N PREMIUM PLUS ’03

engine oil.

2. Fill a pressure prelubricator (J 39258-A) with

the recommended oil and connect the

pressure prelubricator to the main oil gallery.

Prime the engine lubrication system for a

minimum of five minutes to ensure a

sufficient supply of oil to all respective parts

and components.

3. Remove the oil level dipstick and check the

crankcase level. Add sufficient oil, if

necessary, to bring it to the FULL mark on

the dipstick. Do not overfill.

Turbocharger

1. Remove and flush the turbocharger oil

supply line with a suitable, clean,

non-flammable solvent, Allow solvent to run

through the line to flush any debris, then

blow the line dry with clean compressed air.

A turbocharger failure can result in debris

contaminating the turbocharger oil supply line. It

is EXTREMELY IMPORTANT to remove, flush

and thoroughly clean the line prior to starting the

engine. Failure to do so can result in debris from

the oil line entering the turbocharger, causing

damage to the bearings and eventual failure of

the turbocharger.

Refer to “TURBOCHARGER FAILURE AND

ACTIONS REQUIRED TO AVOID REPEAT

FAILURE” to acquire more information regarding

the procedures required to avoid a repeat

turbocharger failure. The text of these procedures

is included in the APPENDIX section.

2. Reconnect the oil supply line to the external

junction block, but allow the oil supply line to

the turbocharger to remain disconnected.

3. Remove the turbocharger air inlet duct.

4. Fill the oil inlet port to overflowing with clean

engine oil. Next, using your fingers at the

compressor wheel, carefully spin and wiggle

the turbocharger shaft to distribute the oil

over all bearing surfaces. Then, again fill the

oil inlet port to overflowing.

5. Install the turbocharger air inlet duct and

reconnect the oil supply line at the

turbocharger.

It is also necessary to perform the above

turbocharger pre-lubrication procedure anytime

the vehicle has not been operated for a period

exceeding 30 days to avoid damage to the

turbocharger. During this extended period, all oil

will have drained away from the bearing and shaft

surfaces.

Cooling System

1. Check the cooling system. Make sure all

plugs are installed and tight. Make sure the

thermostat(s) is installed.

2. Install a

new

coolant conditioner if so

equipped.

3. Fill the system with the recommended

coolant.

To ensure that all air is purged from the cooling

system, remove a plug from the top (or end) of

the coolant manifold during filling. This will

eliminate any air that is trapped as a result of

rapid filling.

5-111.bk Page 463 Monday, July 10, 2006 2:26 PM

Содержание ASET AC

Страница 6: ...TABLE OF CONTENTS Page iii TABLE OF CONTENTS 5 111 bk Page iii Monday July 10 2006 2 26 PM...

Страница 14: ...INTRODUCTION Page 1 INTRODUCTION 5 111 bk Page 1 Monday July 10 2006 2 26 PM...

Страница 23: ...Page 10 NOTES 5 111 bk Page 10 Monday July 10 2006 2 26 PM...

Страница 24: ...VISUAL IDENTIFICATION Page 11 VISUAL IDENTIFICATION 5 111 bk Page 11 Monday July 10 2006 2 26 PM...

Страница 28: ...DESCRIPTION AND OPERATION Page 15 DESCRIPTION AND OPERATION 5 111 bk Page 15 Monday July 10 2006 2 26 PM...

Страница 96: ...COMPONENT LOCATOR Page 83 COMPONENT LOCATOR 5 111 bk Page 83 Monday July 10 2006 2 26 PM...

Страница 99: ...Page 86 NOTES 5 111 bk Page 86 Monday July 10 2006 2 26 PM...

Страница 100: ...TROUBLESHOOTING Page 87 TROUBLESHOOTING 5 111 bk Page 87 Monday July 10 2006 2 26 PM...

Страница 140: ...MAINTENANCE Page 127 MAINTENANCE 5 111 bk Page 127 Monday July 10 2006 2 26 PM...

Страница 153: ...Page 140 NOTES 5 111 bk Page 140 Monday July 10 2006 2 26 PM...

Страница 154: ...REPAIR INSTRUCTIONS PART 1 Page 141 REPAIR INSTRUCTIONS PART 1 5 111 bk Page 141 Monday July 10 2006 2 26 PM...

Страница 383: ...Page 370 NOTES 5 111 bk Page 370 Monday July 10 2006 2 26 PM...

Страница 384: ...REPAIR INSTRUCTIONS PART 2 Page 371 REPAIR INSTRUCTIONS PART 2 5 111 bk Page 371 Monday July 10 2006 2 26 PM...

Страница 454: ...REPAIR INSTRUCTIONS PART 3 Page 441 REPAIR INSTRUCTIONS PART 3 5 111 bk Page 441 Monday July 10 2006 2 26 PM...

Страница 479: ...Page 466 NOTES 5 111 bk Page 466 Monday July 10 2006 2 26 PM...

Страница 480: ...SPECIFICATIONS Page 467 SPECIFICATIONS 5 111 bk Page 467 Monday July 10 2006 2 26 PM...

Страница 505: ...Page 492 NOTES 5 111 bk Page 492 Monday July 10 2006 2 26 PM...

Страница 506: ...SCHEMATIC ROUTING DIAGRAMS Page 493 SCHEMATIC ROUTING DIAGRAMS 5 111 bk Page 493 Monday July 10 2006 2 26 PM...

Страница 513: ...Page 500 NOTES 5 111 bk Page 500 Monday July 10 2006 2 26 PM...

Страница 514: ...SPECIAL TOOLS EQUIPMENT Page 501 SPECIAL TOOLS EQUIPMENT 5 111 bk Page 501 Monday July 10 2006 2 26 PM...

Страница 519: ...Page 506 NOTES 5 111 bk Page 506 Monday July 10 2006 2 26 PM...

Страница 520: ...APPENDIX Page 507 APPENDIX 5 111 bk Page 507 Monday July 10 2006 2 26 PM...

Страница 528: ...INDEX Page 515 INDEX Index fm Page 515 Monday July 10 2006 2 48 PM...

Страница 535: ...Page 522 NOTES Index fm Page 522 Monday July 10 2006 2 48 PM...