March 2000 © TOSHIBA TEC

8-89

DP120F/DP125F Removal/Replacement

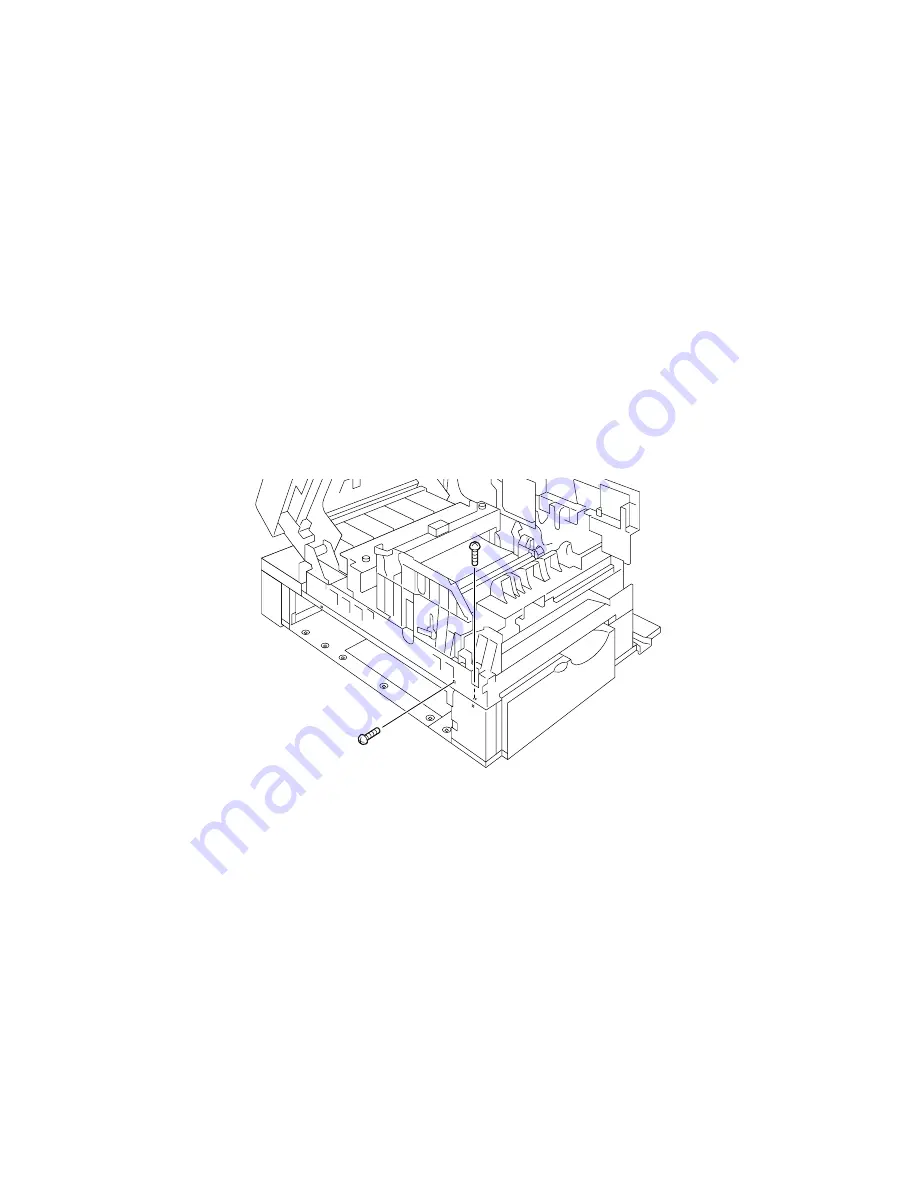

2.4.20 Main Block

Before disassembling or reassembling, be sure to refer to “1. Before Disassembling or Reas-

sembling.”

(1)

Remove the rear cover. (Refer to “2.1.5 Rear Cover.”)

(2)

Remove the front cover assembly. (Refer to “2.1.6 Front Cover.”)

(3)

Remove the right side cover. (Refer to “2.1.7 Right Side Cover.”)

(4)

Remove the left side upper cover. (Refer to “2.1.8 Left Side Upper Cover.”)

(5)

Remove the left side lower cover. (Refer to “2.1.9 Left Side Lower Cover.”)

(6)

Remove the rear side frame. (Refer to “2.4.3 Rear Side Frame.”)

(7)

Remove the two screws from the front side of the main block.

08-02-111

Fig. 8-2-111

Summary of Contents for DP120F

Page 1: ...PLAINPAPERFACSIMILE File No 31200001 R0112216901 TTEC ...

Page 401: ...DP120F DP125F Circuit Description 7 92 March 2000 TOSHIBA TEC 07 05 00 Fig 7 5 1 ...

Page 656: ...DP120F DP125F Troubleshooting 11 44 March 2000 TOSHIBA TEC ...

Page 700: ...DP120F DP125F Appendix 12 2 March 2000 TOSHIBA TEC 1 2 Error Count List ...

Page 701: ...March 2000 TOSHIBA TEC 12 3 DP120F DP125F Appendix 1 3 Function List for Maintenance ...

Page 702: ...DP120F DP125F Appendix 12 4 March 2000 TOSHIBA TEC 1 4 Drum Unit ...

Page 703: ...March 2000 TOSHIBA TEC 12 5 DP120F DP125F Appendix 1 5 Memory Dump List ...

Page 706: ...SHUWA SHIBA PARK BLDG A 2 4 1 SHIBA KOEN MINATO KU TOKYO 105 8524 JAPAN ...