3860/80 User’s Manual

10-8

Continuous Envelopes

Continuous envelopes that are packaged on sprocket-feed strips should be fed from the

BOTTOM paper path.

Any continuous envelopes designed for impact-matrix printing should work well in the printer,

but test an envelope design before committing to it. The overfolds of envelopes can be a

problem. The print gap must be set so the thickest part of the envelope does not get

smudged; this may be more print gap than is needed for optimum print quality.

For problem envelopes, experiment with the print impact,

Wire Imp,

from the LCD menu.

Clean Up After Nonbonded Paper

If the paper has a high lint or dust content, paper dust may combine with the ink on the ribbon

to form a paste. This paste may accumulate in the ribbon cartridge and on the ribbon guide. It

may also build up on the face of the print head and restrict the movement of the print wires.

The following symptoms appear after a short operating period:

•

fuzzy characters

•

intermittent gaps or missing dots

•

light printing occurring before the expected end-of-life of the ribbon

Correct this as follows:

Turn the printer off.

Remove the ribbon cartridge.

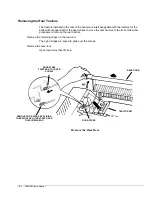

Clean the ribbon guide

Use a foam swap dipped in rubbing alcohol to wipe away accumulated paste.

DO NOT

use

rubbing alcohol with additives like witch hazel or wintergreen.

Clean the face of the print head.

Gently wipe away accumulated paste using a foam swab dipped in rubbing alcohol. Loosen

the print head mounting screws to tip the print head up so it’s more accessible, but

DO NOT

unplug the connector.

Secure the print head.

Replace the ribbon.