LCD Head Gap Menu 7-1

Chapter 7 LCD Head Gap Menu

The print head gap on dual path printers may be controlled from the LCD menu. Print head

gap is the distance from the print head nozzle to the striker bar. Maintaining the correct print

head gap is critical to good print quality and print head life. If the gap is too small, characters

will smudge and the ribbon may snag on the print wires. If the gap is too large, the print quality

will be poor, the printer will be noisier, and may increase print head wear.

Single paper path printers require manual adjustment of the print head gap. The LCD Menu

will not display the Head Gap options on single path printers.

As shipped, dual path printers are set to automatically adjust the print head gap each time a

form is loaded.

Semiautomatic head gap adjustment allows preset print head gaps to be applied to any paper

path.

Semiautomatic head gap adjustment may be used in one paper path and automatic print head

gap adjustment used in another.

From the LCD main menu

Prog:Utility

, select

Utility:Prnt Stat

to print a status that shows the

print head gap mode and offset settings for the active format. Select

Utilit:PR Format

to print

the same information for the four stored formats.

Print head gap control is available only from the LCD menu. Neither host commands nor the

Printed Menu offer any control over the print head gap.

Auto Head Gap Adjust

The advantage of auto head gap is that the operator never needs to adjust the print head gap,

except perhaps as the ribbon wears. Forms of various thicknesses may be loaded into the

different paper paths and the print head gap will adjust to match the form.

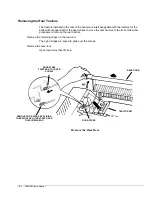

How Auto Head Gap Adjust Works

If there is no paper in front of the print head or when the top cover is opened, the print head

will back away from the striker bar as far as possible.

When dual path printers are set to Auto Head Gap Adjust (as shipped), loading a paper path

will cause the following actions:

Pressing the FF/Load key will load paper in the selected path to the top print reference.

The carriage and print head move to a position over the paper-out sensor. One of the print

wires in the print head is extended.

The auto gap mechanism moves the print head toward the paper. The extended print wire

contacts the paper through the ribbon and is pushed back. The motion of the print wire is

detected and the position of the print head is used to establish the thickness of the

ribbon/paper combination.

The auto gap mechanism moves the print head to the optimal print gap.