36

2.7 Setting the Roll Sheets

Notes

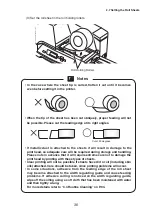

(3) Set the roll sheet in the roll holding rollers.

Roll Holding Rollers

• In the case where the sheet tip is curled, flatten it out until it becomes

even before setting it in the printer.

• When the tip of the sheet has been cut obliquely, proper feeding will not

be possible. Please cut the leading edge at its right angles.

Cut at 90 degrees.

• If metallic dust is attached to the sheets it will result in damage to the

print head, so adequate care will be required during storage and handling.

Please note in advance that it will require extreme care not to damage the

print head by printing with these types of sheets.

• Clear printing will not be possible if sheets have dirt or oil (including skin

oils) attached. Care should be taken, since printing problems will occur.

• In some situations, adhesive from the leading edge of the roll sheet

may become attached to the width regulating guide and cause feeding

problems. If adhesive soiling is noticed on the width regulating guide,

wipe off the soiling using a soft cloth that has been moistened with water

and then tightly wrung.

For more details, refer to “4.4 Routine Cleaning” on P.94.