33

33

2.6 Setting the Plates

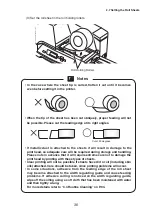

(4) Holding the ridged surfaces of the width regulating guide (close to the locking

screw), match the width regulating guide to the plate width.

Depending on the position of holding the width regulating guide, the width

regulating guide may not move smoothly. Please hold the ridged surfaces

when matching the plate width.

Ridged Surfaces

Width Regulating Guide

• If the width regulating guide is set too tightly, or if there is a gap between

the width regulating guide and the plate, the plate will not be fed straight.

Move the width regulating guide until it is lightly touching the plate.

• Adhesive attached to the width regulating guide may cause feeding

problems. If adhesive soiling is noticed on the width regulating guide,

wipe off the soiling using a soft cloth that has been moistened with water

and then tightly wrung.

For more details, refer to “4.4 Routine Cleaning” on P.94.

(5) Tighten the locking screw to fix the width regulating guide.

Locking Screw

When tightening the locking screw, take care not to over-tighten it. In

addition, when loosening the locking screw, it should only be loosened far

enough so that the width regulating guide can be moved. This requires

close care since if it is loosened further, it will cause damage to the screw.

Notes

Note