10-M2

M8540, M9540, WSM

CABIN

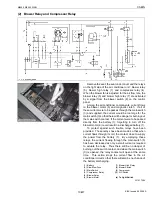

[2] COMPRESSOR

The vane type compressor installed on this cabin is

composed of a cylinder (1) with an oval cross section and

a rotor (2) with five vanes (3). The vane type compressor

is provided with two suction ports and two discharge

ports respectively.

The five vanes (3) mounted on the rotor (2), rotating

along the inner wall of the cylinder (1), keeps air-

tightness using the centrifugal force of the rotor (2) and

the back pressure of the vanes (3) that grow in proportion

to the rotating speed of the rotor (2).

As a result, the volumes of the five cylinder chambers

separated with the cylinder (1) and the five vanes (3)

change.

For each rotation of the rotor (2), each of the cylinder

chambers performs two cycles of inhalation,

compression, and discharge.

W1012943

Q

Operation

In proportion to the rotation of the rotor (3), a volume

of a cylinder chamber separated with the cylinder (1) and

the vanes (4) increases. The cylinder chamber inhales

refrigerant gas from the suction port (2).

As the rotor (3) rotates further, a volume of the

cylinder chamber separated with the cylinder (1) and the

vanes (4) decreases, and the refrigerant gas is

compressed. As the rotor (3) rotates even further, the

refrigerant gas is highly compressed and then presses

the discharge valve to open. The refrigerant gas is

discharged from the discharge port (5).

W1013091

Q

Compressor Oil

The compressor oil dissolves in the refrigerant, circulates through the air-conditioning cycle, and functions to

lubricate the compressor. But the conventional compressor oil for R12 does not dissolve in R134a, so it does not

circulate through the cycle, and the lifespan of the compressor is considerably shortened.

It is still essential to ensure that the correct refrigerant oil is used. R12 systems were lubricated with mineral oil,

which is totally unsuitable for R134a systems. The letter require PAG oil, which mixes very well with the refrigerant

and provides ideal lubrication throughout the system.

*PAG : Polyalkyleneglycol (Synthetic oil)

(1) Cylinder

(2) Rotor

(3) Vane

(1) Cylinder

(2) Suction Port

(3) Rotor

(4) Vane

(5) Discharge Port

(A) Compression Process

(B) Discharge Process

(C) Suction Process

Quantity (Total)

Brand Name

100 to 120 cc

0.106 to 0.127 U.S.qts.

0.088 to 0.106 Imp.qts.

ND-OIL 8 <PAG* oil>

KiSC issued 09, 2008 A

Summary of Contents for M9540

Page 1: ...M8540 M9540 WORKSHOP MANUAL TRACTOR KiSC issued 09 2008 A...

Page 8: ...6 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 9: ...7 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 10: ...8 M8540 M9540 WSM SAFETY INSTRUCTIONS Q CABIN Model KiSC issued 09 2008 A...

Page 11: ...9 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 12: ...10 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 16: ...14 M8540 M9540 WSM DIMENSIONS DIMENSIONS ROPS Model KiSC issued 09 2008 A...

Page 17: ...15 M8540 M9540 WSM DIMENSIONS CABIN Model KiSC issued 09 2008 A...

Page 18: ...G GENERAL KiSC issued 09 2008 A...

Page 103: ...1 ENGINE KiSC issued 09 2008 A...

Page 203: ...2 CLUTCH KiSC issued 09 2008 A...

Page 219: ...3 TRANSMISSION KiSC issued 09 2008 A...

Page 322: ...4 REAR AXLE KiSC issued 09 2008 A...

Page 323: ...CONTENTS MECHANISM 1 FEATURES 4 M1 KiSC issued 09 2008 A...

Page 336: ...5 BRAKES KiSC issued 09 2008 A...

Page 374: ...6 FRONT AXLE KiSC issued 09 2008 A...

Page 401: ...7 STEERING KiSC issued 09 2008 A...

Page 402: ...CONTENTS MECHANISM 1 STEERING MECHANISM 7 M1 2 STEERING CYLINDER 7 M2 KiSC issued 09 2008 A...

Page 420: ...8 HYDRAULIC SYSTEM KiSC issued 09 2008 A...

Page 473: ...9 ELECTRICAL SYSTEM KiSC issued 09 2008 A...

Page 554: ...10 CABIN KiSC issued 09 2008 A...