2-S3

M8540, M9540, WSM

CLUTCH

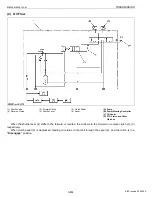

3. TIGHTENING TORQUES

Tightening torques of screws, bolts and nuts on the table below are especially specified.

(For general use screws, bolts and nuts : Refer to “5. TIGHTENING TORQUES” at “G.GENERAL” section.)

W1012736

Item

N·m

kgf·m

lbf·ft

PTO clutch holder mounting screw

23.5 to 27.4

2.4 to 2.8

17.4 to 20.3

KiSC issued 09, 2008 A

Summary of Contents for M9540

Page 1: ...M8540 M9540 WORKSHOP MANUAL TRACTOR KiSC issued 09 2008 A...

Page 8: ...6 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 9: ...7 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 10: ...8 M8540 M9540 WSM SAFETY INSTRUCTIONS Q CABIN Model KiSC issued 09 2008 A...

Page 11: ...9 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 12: ...10 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 16: ...14 M8540 M9540 WSM DIMENSIONS DIMENSIONS ROPS Model KiSC issued 09 2008 A...

Page 17: ...15 M8540 M9540 WSM DIMENSIONS CABIN Model KiSC issued 09 2008 A...

Page 18: ...G GENERAL KiSC issued 09 2008 A...

Page 103: ...1 ENGINE KiSC issued 09 2008 A...

Page 203: ...2 CLUTCH KiSC issued 09 2008 A...

Page 219: ...3 TRANSMISSION KiSC issued 09 2008 A...

Page 322: ...4 REAR AXLE KiSC issued 09 2008 A...

Page 323: ...CONTENTS MECHANISM 1 FEATURES 4 M1 KiSC issued 09 2008 A...

Page 336: ...5 BRAKES KiSC issued 09 2008 A...

Page 374: ...6 FRONT AXLE KiSC issued 09 2008 A...

Page 401: ...7 STEERING KiSC issued 09 2008 A...

Page 402: ...CONTENTS MECHANISM 1 STEERING MECHANISM 7 M1 2 STEERING CYLINDER 7 M2 KiSC issued 09 2008 A...

Page 420: ...8 HYDRAULIC SYSTEM KiSC issued 09 2008 A...

Page 473: ...9 ELECTRICAL SYSTEM KiSC issued 09 2008 A...

Page 554: ...10 CABIN KiSC issued 09 2008 A...