8-S30

M8540, M9540, WSM

HYDRAULIC SYSTEM

[5] HYDRAULIC CYLINDER

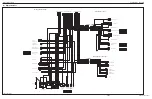

Removing Hydraulic Cylinder

1. Remove the lift rod pin (1).

2. Disconnect the hydraulic hose (2) from hydraulic cylinder.

3. Remove the hydraulic cylinder cover (3).

4. Remove the cylinder pin (upper) (4).

5. Disconnect the breather hose (5) from hydraulic cylinder.

6. Remove the cylinder pin (lower) (6).

7. Take out the hydraulic cylinder.

NOTE

Q

• Take care not to damage the grease nipples when remove

the hydraulic cylinder.

(When reassembling)

• Apply grease to the grease nipples.

• Take care not to damage the grease nipples when reassemble

the hydraulic cylinder.

W1017814

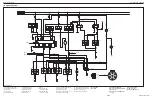

Disassembling Hydraulic Cylinder

1. Remove the liquid gasket from top of head (2).

2. Slightly tap-in the head (2) to inside, and remove the internal

circlip (5) by using the small screwdriver.

3. If the internal circlip (5) cannot be removed by above-mentioned

method, remove it by the following procedure.

- Carefully clamp the cylinder tube (4) in a vise.

- Drill approx. 2.5 mm (0.1 in.) diameter hole on the cylinder tube

(position

A

) just over the internal circlip (5) as shown in figure.

- Use a small screwdriver and remove the internal circlip (5).

Simultaneously support this action by pushing from the outside

of the cylinder tube with another small screwdriver or similar

tool.

4. Remove the rod (1) and head (2).

5. Inject the compressed air through the oil inlet port of the cylinder

tube (4), and remove the piston (3).

6. Remove the external circlip (6), and remove the head (2).

(When reassembling)

• Apply transmission fluid to the piston (3), head (2) and cylinder

tube (4).

• Take care not to damage the O-ring, backup ring and seal.

• Apply liquid gasket (Three Bond 1206C or equivalent) to the top

of head (2), while pressing the head (2) against internal circlip (5).

• After reassembling the cylinder, be sure to close the drilled hole

by liquid gasket.

W1018811

Tightening torque

Cylinder hose retaining nut

45.1 to 53.0 N·m

4.6 to 5.4 kgf·m

33.3 to 39.1 lbf·ft

(1) Lift Rod Pin

(2) Hydraulic Hose

(3) Hydraulic Cylinder Cover

(4) Cylinder Pin (Upper)

(5) Breather Hose

(6) Cylinder Pin (Lower)

(1) Rod

(2) Head

(3) Piston

(4) Cylinder Tube

(5) Internal Circlip

(6) External Circlip

A : Position for drilling

L : 6.0 mm (0.236 in.)

KiSC issued 09, 2008 A

Summary of Contents for M9540

Page 1: ...M8540 M9540 WORKSHOP MANUAL TRACTOR KiSC issued 09 2008 A...

Page 8: ...6 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 9: ...7 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 10: ...8 M8540 M9540 WSM SAFETY INSTRUCTIONS Q CABIN Model KiSC issued 09 2008 A...

Page 11: ...9 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 12: ...10 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 16: ...14 M8540 M9540 WSM DIMENSIONS DIMENSIONS ROPS Model KiSC issued 09 2008 A...

Page 17: ...15 M8540 M9540 WSM DIMENSIONS CABIN Model KiSC issued 09 2008 A...

Page 18: ...G GENERAL KiSC issued 09 2008 A...

Page 103: ...1 ENGINE KiSC issued 09 2008 A...

Page 203: ...2 CLUTCH KiSC issued 09 2008 A...

Page 219: ...3 TRANSMISSION KiSC issued 09 2008 A...

Page 322: ...4 REAR AXLE KiSC issued 09 2008 A...

Page 323: ...CONTENTS MECHANISM 1 FEATURES 4 M1 KiSC issued 09 2008 A...

Page 336: ...5 BRAKES KiSC issued 09 2008 A...

Page 374: ...6 FRONT AXLE KiSC issued 09 2008 A...

Page 401: ...7 STEERING KiSC issued 09 2008 A...

Page 402: ...CONTENTS MECHANISM 1 STEERING MECHANISM 7 M1 2 STEERING CYLINDER 7 M2 KiSC issued 09 2008 A...

Page 420: ...8 HYDRAULIC SYSTEM KiSC issued 09 2008 A...

Page 473: ...9 ELECTRICAL SYSTEM KiSC issued 09 2008 A...

Page 554: ...10 CABIN KiSC issued 09 2008 A...