1-S20

M8540, M9540, WSM

ENGINE

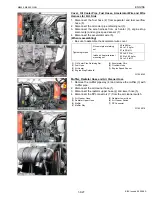

Fuel Tightness of Pump Element

1. Remove the engine stop solenoid.

2. Remove the injection pipes.

3. Install the injection pump pressure tester (refer to “8. SPECIAL

TOOLS” at “G. GENERAL” section) to the injection pump.

4. Install the injection nozzle (2) jetted with the proper injection

pressure to the injection pump pressure tester (1). (Refer to the

figure.)

5. Set the speed control lever to the maximum speed position.

6. Run the starter to increase the pressure.

7. If the pressure can not reach the allowable limit, replace the

pump with new one or repair with a Kubota-authorized pump

service shop.

NOTE

Q

• Never try to disassemble the injection pump assembly. For

repairs, you are strongly requested to contact a Kubota-

authorized pump service shop.

W1017430

Fuel Tightness of Delivery Valve

1. Remove the engine stop solenoid.

2. Remove the injection pipes.

3. Set a pressure tester (refer to “8. SPECIAL TOOLS” at “G.

GENERAL” section) to the fuel injection pump.

4. Install the injection nozzle (2) jetted with the proper injection

pressure to the injection pump pressure tester (1).

5. Run the starter to increase the pressure.

6. Stop the starter when the fuel jets from the injection nozzle. After

that, turn the flywheel by the hand and raise the pressure to

approx. 18.63 MPa (190 kgf/cm

2

, 2702 psi).

7. Now turn the flywheel back about half a turn (to keep the plunger

free). Maintain the flywheel at this position and clock the time

taken for the pressure to drop from 18.63 to 17.65 MPa (from 190

to 180 kgf/cm

2

, from 2702 to 2560 psi).

8. Measure the time needed to decrease the pressure from 18.63 to

17.65 MPa (from 190 to 180 kgf/cm

2

, from 2702 to 2560 psi).

9. If the measurement is less than allowable limit, replace the pump

with new one or repair with a Kubota-authorized pump service

shop.

NOTE

Q

• Never try to disassemble the injection pump assembly. For

repairs, you are strongly requested to contact a Kubota-

authorized pump service shop.

W1017786

Fuel tightness of pump

element

Allowable limit

18.63 MPa

190.0 kgf/cm

2

2702 psi

(1) Injection Pump Pressure Tester

(2) Injection Nozzle

(3) Protection Cover for Jetted Fuel

Fuel tightness of

delivery valve

Factory spec.

10 seconds

18.63

→

17.65 MPa

190.0

→

180.0 kgf/cm

2

2702

→

2560 psi

Allowable limit

5 seconds

18.63

→

17.65 MPa

190.0

→

180.0 kgf/cm

2

2702

→

2560 psi

(1) Injection Pump Pressure Tester

(2) Injection Nozzle

(3) Protection Cover for Jetted Fuel

KiSC issued 09, 2008 A

Summary of Contents for M9540

Page 1: ...M8540 M9540 WORKSHOP MANUAL TRACTOR KiSC issued 09 2008 A...

Page 8: ...6 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 9: ...7 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 10: ...8 M8540 M9540 WSM SAFETY INSTRUCTIONS Q CABIN Model KiSC issued 09 2008 A...

Page 11: ...9 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 12: ...10 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 16: ...14 M8540 M9540 WSM DIMENSIONS DIMENSIONS ROPS Model KiSC issued 09 2008 A...

Page 17: ...15 M8540 M9540 WSM DIMENSIONS CABIN Model KiSC issued 09 2008 A...

Page 18: ...G GENERAL KiSC issued 09 2008 A...

Page 103: ...1 ENGINE KiSC issued 09 2008 A...

Page 203: ...2 CLUTCH KiSC issued 09 2008 A...

Page 219: ...3 TRANSMISSION KiSC issued 09 2008 A...

Page 322: ...4 REAR AXLE KiSC issued 09 2008 A...

Page 323: ...CONTENTS MECHANISM 1 FEATURES 4 M1 KiSC issued 09 2008 A...

Page 336: ...5 BRAKES KiSC issued 09 2008 A...

Page 374: ...6 FRONT AXLE KiSC issued 09 2008 A...

Page 401: ...7 STEERING KiSC issued 09 2008 A...

Page 402: ...CONTENTS MECHANISM 1 STEERING MECHANISM 7 M1 2 STEERING CYLINDER 7 M2 KiSC issued 09 2008 A...

Page 420: ...8 HYDRAULIC SYSTEM KiSC issued 09 2008 A...

Page 473: ...9 ELECTRICAL SYSTEM KiSC issued 09 2008 A...

Page 554: ...10 CABIN KiSC issued 09 2008 A...

![Whirlpool [12:36:03] ?????????????????: GC900QPPB Use & Care Manual preview](http://thumbs.mh-extra.com/thumbs/whirlpool/12-36-03-gc900qppb/12-36-03-gc900qppb_use-and-care-manual_437149-01.webp)