1-S75

M8540, M9540, WSM

ENGINE

Connecting Rod Alignment

NOTE

Q

• Since the I.D. of the connecting rod small end bushing is the

basis of this check, check the bushing for wear beforehand.

1. Remove the piston pin in the connecting rod.

2. Install the piston pin in the connecting rod.

3. Install the connecting rod on the connecting rod alignment tool.

4. Put a gauge over the piston pin, and move it against the face

plate.

5. If the gauge does not fit squarely against the face plate, measure

the space between the pin of the gauge and the face plate.

6. If the measurement exceeds the allowable limit, replace the

connecting rod.

W1066581

(4) Crankshaft

Crankshaft Side Clearance

1. Set a dial indicator with its tip on the end of the crankshaft.

2. Measure the side clearance by moving the crankshaft to the front

and rear.

3. If the measurement exceeds the allowable limit, replace the

thrust bearings.

4. If the same size bearing is useless because of the crankshaft

journal wear, replace it with an oversize one referring to the table

and figure.

(Reference)

• Oversize dimensions of crankshaft journal.

W1066738

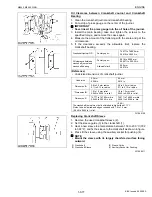

Crankshaft Alignment

1. Support the crankshaft with V block on the surface plate and set

a dial indicator with its tip on the intermediate journal at right

angle.

2. Rotate the crankshaft on the V block and get the misalignment

(half of the measurement).

3. If the misalignment exceeds the allowable limit, replace the

crankshaft.

W1067285

Connecting rod

alignment

Allowable limit

0.05 mm

0.0020 in.

Crankshaft side

clearance

Factory spec.

0.15 to 0.31 mm

0.0059 to 0.012 in.

Allowable limit

0.50 mm

0.020 in.

Oversize

0.2 mm

0.008 in.

0.4 mm

0.016 in.

Dimension

A

29.20 to 29.25 mm

1.1496 to 1.1515 in.

29.40 to 29.45 mm

1.1574 to 1.1594 in.

Dimension

B

169.1 to 169.15 mm

6.6575 to 6.6594 in.

169.2 to 169.25 mm

6.6614 to 6.6634 in.

Dimension

C

2.8 to 3.2 mm radius

0.1102 to 0.1260 in. radius

2.8 to 3.2 mm radius

0.1102 to 0.1260 in. radius

(0.8-S)

The crankshaft journal must be fine-finished to higher than

∇∇∇∇.

Crankshaft alignment

Allowable limit

0.02 mm

0.0008 in.

KiSC issued 09, 2008 A

Summary of Contents for M9540

Page 1: ...M8540 M9540 WORKSHOP MANUAL TRACTOR KiSC issued 09 2008 A...

Page 8: ...6 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 9: ...7 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 10: ...8 M8540 M9540 WSM SAFETY INSTRUCTIONS Q CABIN Model KiSC issued 09 2008 A...

Page 11: ...9 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 12: ...10 M8540 M9540 WSM SAFETY INSTRUCTIONS KiSC issued 09 2008 A...

Page 16: ...14 M8540 M9540 WSM DIMENSIONS DIMENSIONS ROPS Model KiSC issued 09 2008 A...

Page 17: ...15 M8540 M9540 WSM DIMENSIONS CABIN Model KiSC issued 09 2008 A...

Page 18: ...G GENERAL KiSC issued 09 2008 A...

Page 103: ...1 ENGINE KiSC issued 09 2008 A...

Page 203: ...2 CLUTCH KiSC issued 09 2008 A...

Page 219: ...3 TRANSMISSION KiSC issued 09 2008 A...

Page 322: ...4 REAR AXLE KiSC issued 09 2008 A...

Page 323: ...CONTENTS MECHANISM 1 FEATURES 4 M1 KiSC issued 09 2008 A...

Page 336: ...5 BRAKES KiSC issued 09 2008 A...

Page 374: ...6 FRONT AXLE KiSC issued 09 2008 A...

Page 401: ...7 STEERING KiSC issued 09 2008 A...

Page 402: ...CONTENTS MECHANISM 1 STEERING MECHANISM 7 M1 2 STEERING CYLINDER 7 M2 KiSC issued 09 2008 A...

Page 420: ...8 HYDRAULIC SYSTEM KiSC issued 09 2008 A...

Page 473: ...9 ELECTRICAL SYSTEM KiSC issued 09 2008 A...

Page 554: ...10 CABIN KiSC issued 09 2008 A...