Electrical connection

Proline Prowirl F 200 PROFIBUS PA

40

Hauser

Connecting cable (option "mass pressure-/temperature-compensated")

8. Disconnect both signal cables from the connection board of the wall housing. by

pressing in the locking clip on the connector. Remove the transmitter housing.

9. Guide the connecting cable through the cable entry and into the connection housing

(if using a connecting cable without an M12 device plug, use the shorter stripped end

of the connecting cable).

10. Wire the connecting cable:

Terminal 1 = brown cable

Terminal 2 = white cable

Terminal 3 = green cable

Terminal 4 = red cable

Terminal 5 = black cable

Terminal 6 = yellow cable

Terminal 7 = blue cable

11. Connect the cable shield via the cable strain relief.

12. Tighten the screws for the cable strain relief using a torque in the range of

1.2 to 1.7 Nm.

13. Reverse the removal procedure to reassemble the transmitter housing.

7.2.3

Ensuring potential equalization

Requirements

Please consider the following to ensure correct measurement:

• Same electrical potential for the medium and sensor

• Remote version: same electrical potential for the sensor and transmitter

• Company-internal grounding concepts

• Pipe material and grounding

7.3

Ensuring the degree of protection

The measuring device fulfills all the requirements for the IP66/67 degree of protection,

Type 4X enclosure.

To guarantee IP66/67 degree of protection, Type 4X enclosure, carry out the following

steps after the electrical connection:

1. Check that the housing seals are clean and fitted correctly.

2. Dry, clean or replace the seals if necessary.

3. Tighten all housing screws and screw covers.

4. Firmly tighten the cable glands.

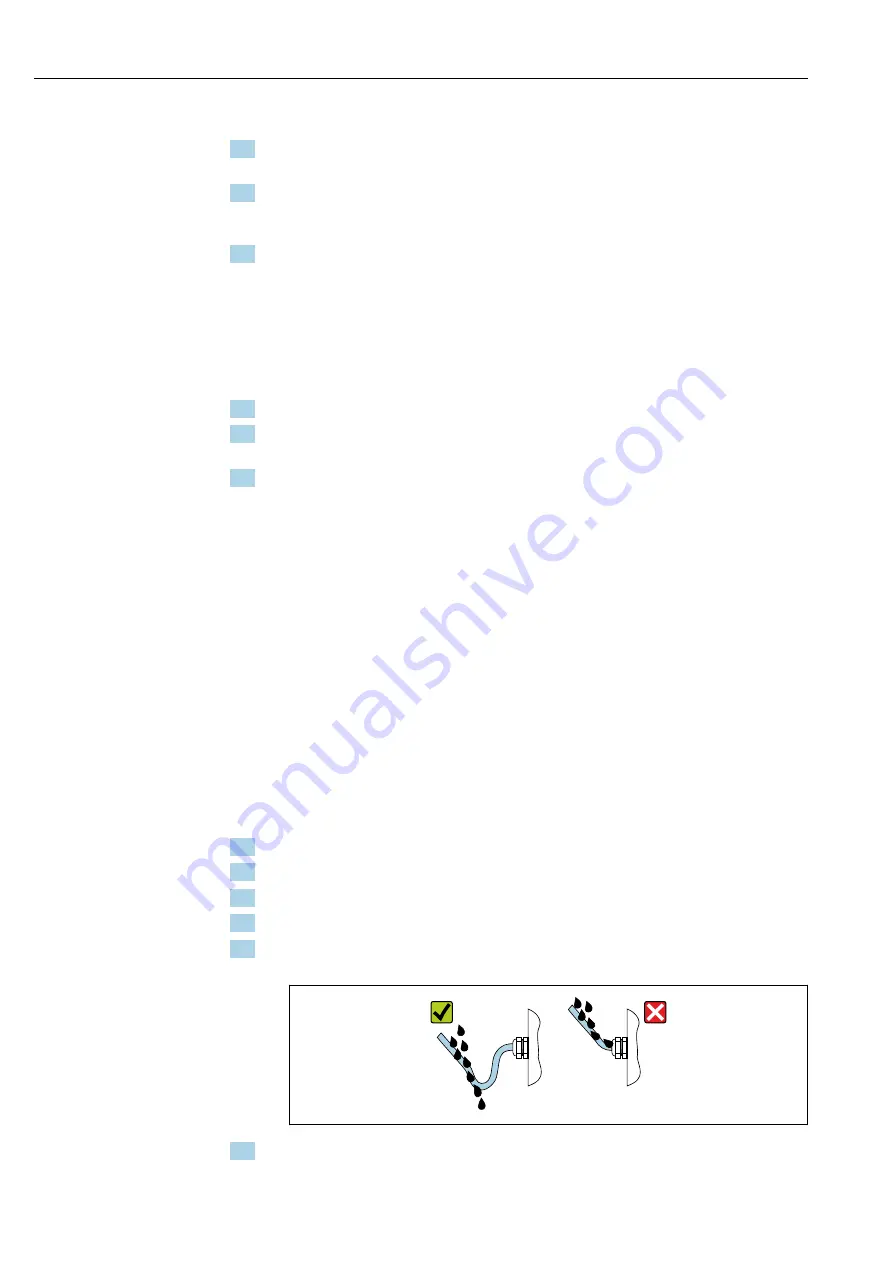

5. To ensure that moisture does not enter the cable entry:

Route the cable so that it loops down before the cable entry ("water trap").

A0029278

6. Insert dummy plugs into unused cable entries.

Summary of Contents for Proline Prowirl F 200

Page 224: ...www addresses endress com...