February 2013

3-63

ColorQube® 9303 Family

IQ 17

Image Quality

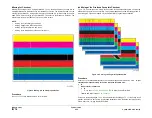

IQ 17 Gloss Marks in the Cross-Process Direction RAP

Use this RAP when the output has gloss marks in the cross process direction.

Typical defects include:

•

Chatter, refer to

Figure 1

. The cleaning unit metering blade is vibrating as it spreads oil

onto the drum. Trace amounts of chatter on duplex is normal.

•

Insufficient oil. Insufficient oil causes the inked sheet to appear glossier than normal and

may also have cross-process cracking marks. This defect can also be caused by high

drum temperature.

•

Jagged streaks, refer to

Figure 1

. The metering blade is leaving excess oil on the drum.

•

When the registration/preheat assembly is too hot, on a duplex print, the side that is face

up in the output tray can have significantly lower gloss than the side that is face down.

•

Gloss band. Some print sequences may result in a gloss band, usually 2 to 3 inches wide,

that may be visible under some lighting conditions. This is normal.

•

Duplex gloss marks may appear for the first several duplex sheets following a simplex

print job. Gloss marks will likely diminish after several prints. This is normal.

Ensure

IQ 1

Image Quality Entry RAP is performed before starting this RAP.

Initial Actions

WARNING

Ensure that the electricity to the machine is switched off while performing tasks that do

not need electricity. Refer to

GP 14

. Disconnect the power cord. Electricity can cause

death or injury. Moving parts can cause injury.

WARNING

Do not clean the stripper blade. The stripper blade is very sharp and can cause injury. If

the stripper blade is dirty a new blade must be installed.

WARNING

Take care during this procedure. Sharp edges may be present that can cause injury.

Press the Machine Status button on the keypad, select the Fault tab on the UI, then Current

Messages. If the message ‘Cleaning unit life extended, image quality may be impacted’ is dis-

played, install a new cleaning unit,

PL 94.10 Item 21

.

Procedure

Print 3 simplex copies of TP 6 Red Solid Fill Test Pages (

TP 2 to TP 10

). Evaluate the final test

page only for metering blade chatter, refer to

Figure 1

. The test pages are good.

Y

N

Install a new cleaning unit,

PL 94.10 Item 21

. Print 3 simplex copies of TP 6 Red Solid Fill

Test Pages (

TP 2 to TP 10

). Inspect the final test page only for metering blade chatter,

refer to

Figure 1

. Chatter is present.

Y

N

Perform

SCP 5

Final Actions.

Re-install the original cleaning unit. The problem is not in the cleaning unit. Re-define the

image quality defect, refer to

IQ 1

Image Quality Entry RAP.

Print 5 duplex copies of TP 6 Red Solid Fill Test Pages (

TP 2 to TP 10

). Inspect the final test

page only for metering blade chatter, refer to

Figure 1

. The test pages are good.

Y

N

Install a new cleaning unit,

PL 94.10 Item 21

. Print 5 duplex copies of TP 6 Red Solid Fill

Test Pages (

TP 2 to TP 10

). Inspect the final test page only for metering blade chatter,

refer to

Figure 1

. The test pages are good.

Y

N

Re-install the original cleaning unit. The problem is not in the cleaning unit. Re-

define the image quality defect, refer to

IQ 1

Image Quality Entry RAP.

Check the cleaning unit metering blade for pieces of paper.

NOTE: Ink pixel build up on the metering blade is normal and should not be cleaned off.

The metering blade is good.

Y

N

Clean the metering blade of paper debris.

Enter

dC959

Cleaning Unit Exerciser and run the slow speed exerciser. The slow speed

exerciser completes successfully.

Y

N

Go to

94-520-00

Cleaning Unit Drive Error RAP.

Open the front door and remove the inner cover. Enter

dC959

, Cleaning Unit Exerciser,

and run the slow speed exerciser. While this is running ensure the cleaning unit metering

blade and roller are making contact with the drum. The metering blade and roller are

making contact with the drum.

Y

N

Check the cleaning unit cams mechanism

PL 94.10 Item 9

,

PL 94.10 Item 13

and

the cleaning unit drive gear and motor

PL 94.10 Item 23

,

PL 94.10 Item 24

. Install

new parts as necessary.

Check that the front drum thermistor,

PL 94.20 Item 9

and the rear drum thermistor,

PL

94.20 Item 10

are not bent or misaligned. Check for paper debris between the thermistors

and the drum and ensure that the thermistors are making good contact with the drum.

The thermistors are good.

Y

N

Install new components as necessary

•

Front drum thermistor,

PL 94.20 Item 9

•

Rear drum thermistor,

PL 94.20 Item 10

Perform

dC335

Heater Monitor and Exerciser. Check the drum operating temperature.

The drum temperature is good.

Y

N

Go to

94-536-00, 94-538-00, 94-540-00, 94-542-00, 94-544-00, 94-546-00, 94-632-

00, 94-633-00

Drum Heat Error RAP.

The machine is operating within specification. Perform

SCP 5

Final Actions.

Re-define the image quality defect, refer to

IQ 1

Image Quality Entry RAP.

A

A

Содержание ColorQube 9303 Series

Страница 1: ...Xerox ColorQube 9303 Family Service Manual 708P90290 February 2013...

Страница 4: ...February 2013 ii ColorQube 9303 Family Introduction...

Страница 18: ...February 2013 1 2 ColorQube 9303 Family Service Call Procedures...

Страница 92: ...February 2013 2 68 ColorQube 9303 Family 05F Status Indicator RAPs...

Страница 104: ...February 2013 2 80 ColorQube 9303 Family 12 701 00 65 Status Indicator RAPs...

Страница 200: ...February 2013 2 176 ColorQube 9303 Family 12N 171 Status Indicator RAPs...

Страница 292: ...February 2013 2 268 ColorQube 9303 Family 16D Status Indicator RAPs...

Страница 320: ...February 2013 2 296 ColorQube 9303 Family 42 504 00 42 505 00 Status Indicator RAPs...

Страница 500: ...February 2013 2 476 ColorQube 9303 Family 94B Status Indicator RAPs...

Страница 648: ...February 2013 3 2 ColorQube 9303 Family Image Quality...

Страница 653: ...February 2013 3 7 ColorQube 9303 Family IQ 1 Image Quality Figure 1 IQ defects 1...

Страница 654: ...February 2013 3 8 ColorQube 9303 Family IQ 1 Image Quality Figure 2 IQ defects 2...

Страница 655: ...February 2013 3 9 ColorQube 9303 Family IQ 1 Image Quality Figure 3 IQ defects 3...

Страница 656: ...February 2013 3 10 ColorQube 9303 Family IQ 1 Image Quality Figure 4 IQ defects 4...

Страница 657: ...February 2013 3 11 ColorQube 9303 Family IQ 1 Image Quality Figure 5 IQ defects 5...

Страница 658: ...February 2013 3 12 ColorQube 9303 Family IQ 1 Image Quality Figure 6 IQ defects 6...

Страница 659: ...February 2013 3 13 ColorQube 9303 Family IQ 1 Image Quality Figure 7 IQ defects 7 Figure 8 IQ defects 8...

Страница 660: ...February 2013 3 14 ColorQube 9303 Family IQ 1 Image Quality Figure 9 IQ defects 9...

Страница 661: ...February 2013 3 15 ColorQube 9303 Family IQ 1 Image Quality Figure 10 IQ defects 10...

Страница 662: ...February 2013 3 16 ColorQube 9303 Family IQ 1 Image Quality Figure 11 IQ defects 11...

Страница 663: ...February 2013 3 17 ColorQube 9303 Family IQ 1 Image Quality Figure 12 IQ defects 12...

Страница 664: ...February 2013 3 18 ColorQube 9303 Family IQ 1 Image Quality Figure 13 IQ defects 13...

Страница 707: ...February 2013 3 61 ColorQube 9303 Family IQ 15 Image Quality Figure 4 Corrupt image data Figure 5 Service test pattern...

Страница 728: ...February 2013 3 82 ColorQube 9303 Family IQ 29 IQ 30 Image Quality...

Страница 736: ...February 2013 3 90 ColorQube 9303 Family TP 15 Image Quality Figure 2 Media path test pages...

Страница 752: ...February 2013 3 106 ColorQube 9303 Family TP 26 Image Quality Figure 1 Print head uniformity colour bands test page...

Страница 758: ...February 2013 3 112 ColorQube 9303 Family IQS 7 IQS 8 Image Quality...

Страница 778: ...February 2013 4 20 ColorQube 9303 Family REP 1 9 Repairs Adjustments...

Страница 794: ...February 2013 4 36 ColorQube 9303 Family REP 3 10 Repairs Adjustments...

Страница 1144: ...February 2013 4 386 ColorQube 9303 Family REP 94 1 Repairs Adjustments...

Страница 1176: ...February 2013 4 418 ColorQube 9303 Family ADJ 62 3 ADJ 62 4 Repairs Adjustments...

Страница 1182: ...February 2013 4 424 ColorQube 9303 Family ADJ 75 3 Repairs Adjustments...

Страница 1184: ...February 2013 4 426 ColorQube 9303 Family ADJ 82 1 Repairs Adjustments...

Страница 1186: ...February 2013 4 428 ColorQube 9303 Family ADJ 91 1 Repairs Adjustments...

Страница 1348: ...February 2013 6 56 ColorQube 9303 Family GP 19 General Procedures Information Figure 1 SIM card matrix...

Страница 1378: ...February 2013 6 86 ColorQube 9303 Family GP 29 General Procedures Information Document Handler DADH Figure 4 DADH Sensor Map...

Страница 1380: ...February 2013 6 88 ColorQube 9303 Family GP 29 General Procedures Information High Volume Finisher HVF Figure 6 HVF Sensor Map...

Страница 1552: ...February 2013 6 260 ColorQube 9303 Family dC140 General Procedures Information...

Страница 1576: ...February 2013 6 284 ColorQube 9303 Family dC640 General Procedures Information...

Страница 1578: ...February 2013 6 286 ColorQube 9303 Family dC708 dC715 General Procedures Information...

Страница 1600: ...February 2013 7 2 ColorQube 9303 Family Wiring Data...

Страница 1696: ...February 2013 8 2 ColorQube 9303 Family Principles of Operation...

Страница 1718: ...February 2013 8 24 ColorQube 9303 Family Principles of Operation Figure 1 Sensors in the media path...

Страница 1808: ...February 2013 8 114 ColorQube 9303 Family Principles of Operation...

Страница 1809: ...XEROX EUROPE...

Страница 1810: ...XEROX EUROPE...

Страница 1811: ...XEROX EUROPE...

Страница 1812: ...XEROX EUROPE...