February 2013

8-38

ColorQube® 9303 Family

Principles of Operation

Feeder

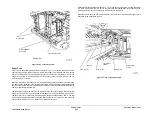

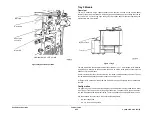

The feed mechanism is a top friction feeder with semi-active retard. The feeder consists of an

input gate, nudger roll, feed roll, and a retard roll. The nudger, feed and retard rolls are Cus-

tomer Replaceable Units, (CRUs).

The nudger and feed rolls are driven by the DADH feed motor, MOT005-074, through an elec-

tromechanical friction feed clutch, CL005-062. A DADH nudger motor, MOT005-098, is oper-

ated to lower the nudger roll to contact the top sheet of the stack while simultaneously

disengaging the input gates until the first sheet is acquired from the stack. The input gates are

prevented from returning to their reset position until after the last sheet is fed off the stack.

The clutch de-energizes and the DADH nudger motor returns to the nudger roll up position,

when the lead edge of the document arrives at the DADH feed sensor, Q005-204, except in the

case of the first sheet, when both the clutch remains energized and the DADH nudger motor

remains at its current position, until the LE of the sheet arrives at the DADH TAR sensor, Q005-

096. When the document is called for, this event being triggered by the TE departure of the

previous sheet from the takeaway sensor, the clutch is re-energized and the (DADH nudger

motor returns to the nudger roll down position), until the LE reaches the take away sensor.

The semi-active retard roll consists of an elastomer-covered outer member and a stationary

inner member, with a wrap spring slip clutch between them. Spring loaded against the feed roll

to provide the required force, the retard rotates during feed and the wrap spring winds until it’s

slip torque is developed, at which point it overruns in the feed direction. The device maintains

this condition when a single sheet is in the pinch. When two sheets are fed into the nip, the tor-

sion spring unwinds, thus turning the retard roll in the reverse direction and driving the multi-fed

sheet backwards out of the feed/retard nip and towards the stack. In the case of singly fed

sheets, the semi-active retard roll is driven in the direction of feed by the motion of the drive

roll.

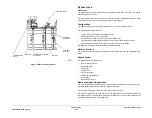

De-skew - Takeaway Rolls (TAR)

Document de-skew and lead edge registration for both simplex and duplex paths are accom-

plished by a combination of the following methods:

•

Document lead edge buckle at TAR - By driving the document with the feed roll assembly

at a higher speed than the TAR rolls, a buckle is formed. This allows the document lead

edge to help correct any skew that exists during this first stage of feeding.

•

Width Guides - The position of the width guides relative to the edges of the stack is the

most important factor in the control of skew within the DADH. Easy movement of the

guides is a requirement to ensure customers can easily obtain a “tight” stack.

Constant Velocity Transport (CVT)

The document is scanned as it passes over the CVT glass with the scan carriage parked

beneath. During this time the document is driven by one large diameter CVT roll and is in con-

tact with a minimum of 2 double nip rolls. The DADH CVT sensor, Q005-097, positioned before

the scan zone, detects the document’s arrival to begin the scan. This sensor also detects the

document’s departure for end of scan or jam detection. Image registration correction occurs at

the image processing PWB.

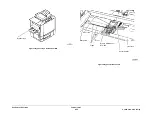

Duplex Inverter

The inverter function is provided by a reversing roll nip. The elements include the nip, a duplex

gate, the feed motor, MOT005-074, and the DADH duplex solenoid, SOL005-100. The docu-

ment is inverted after the trail edge is sensed by the DADH exit sensor, Q005-209. By control-

ling the time beyond the DADH exit sensor, the document is stopped by the DADH feed motor,

Q005-074, after the trail edge passes the duplex gate, but prior to leaving the nip. At this time,

the DADH feed motor is reversed. The DADH feed motor continues to drive the document

along the duplex path, so that it re-enters the original input path. The document lead edge

arriving at the DADH CVT sensor causes the DADH duplex solenoid, SOL005-100, to open.

The DADH CVT Motor continues to feed the document past the scanning position, as in sim-

plex mode. After side 2 is scanned, the document is re-inverted, prior to being re-stacked for

correct document orientation. This is accomplished by sending the document through the

duplex path at maximum speed, without scanning, to the exit.

Re-stack

The document re-stack function is provided by passing the documents through the inverter nip

into a catch tray above the manual platen cover. The profile of the exit tray together with a re-

stack arm ensures an orderly document re-stack.

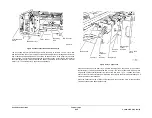

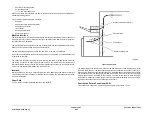

Drives

Refer to

Figure 2

. The DADH is driven by two 24V DC stepper motors. The DADH CVT motor,

MOT005-099, drives the CVT roll by means of a synchronous belt. The DADH feed motor,

Q005-074, provides drive to the feed assembly rolls, TAR assembly and exit roll. The feed

shaft is isolated from the motor by the DADH feed clutch, CL005-062. The DADH feed motor,

Q005-074, drives the exit roll assembly in both forward (exit) and reverse (duplex) directions.

In addition, the DADH duplex solenoid SOL005-100, is required to open the exit / duplex nip

during document inversion in duplex mode. This is necessary because the document is

wrapped around the CVT roll and both the leading and trailing edges are passing through the

exit / duplex nip.

Содержание ColorQube 9303 Series

Страница 1: ...Xerox ColorQube 9303 Family Service Manual 708P90290 February 2013...

Страница 4: ...February 2013 ii ColorQube 9303 Family Introduction...

Страница 18: ...February 2013 1 2 ColorQube 9303 Family Service Call Procedures...

Страница 92: ...February 2013 2 68 ColorQube 9303 Family 05F Status Indicator RAPs...

Страница 104: ...February 2013 2 80 ColorQube 9303 Family 12 701 00 65 Status Indicator RAPs...

Страница 200: ...February 2013 2 176 ColorQube 9303 Family 12N 171 Status Indicator RAPs...

Страница 292: ...February 2013 2 268 ColorQube 9303 Family 16D Status Indicator RAPs...

Страница 320: ...February 2013 2 296 ColorQube 9303 Family 42 504 00 42 505 00 Status Indicator RAPs...

Страница 500: ...February 2013 2 476 ColorQube 9303 Family 94B Status Indicator RAPs...

Страница 648: ...February 2013 3 2 ColorQube 9303 Family Image Quality...

Страница 653: ...February 2013 3 7 ColorQube 9303 Family IQ 1 Image Quality Figure 1 IQ defects 1...

Страница 654: ...February 2013 3 8 ColorQube 9303 Family IQ 1 Image Quality Figure 2 IQ defects 2...

Страница 655: ...February 2013 3 9 ColorQube 9303 Family IQ 1 Image Quality Figure 3 IQ defects 3...

Страница 656: ...February 2013 3 10 ColorQube 9303 Family IQ 1 Image Quality Figure 4 IQ defects 4...

Страница 657: ...February 2013 3 11 ColorQube 9303 Family IQ 1 Image Quality Figure 5 IQ defects 5...

Страница 658: ...February 2013 3 12 ColorQube 9303 Family IQ 1 Image Quality Figure 6 IQ defects 6...

Страница 659: ...February 2013 3 13 ColorQube 9303 Family IQ 1 Image Quality Figure 7 IQ defects 7 Figure 8 IQ defects 8...

Страница 660: ...February 2013 3 14 ColorQube 9303 Family IQ 1 Image Quality Figure 9 IQ defects 9...

Страница 661: ...February 2013 3 15 ColorQube 9303 Family IQ 1 Image Quality Figure 10 IQ defects 10...

Страница 662: ...February 2013 3 16 ColorQube 9303 Family IQ 1 Image Quality Figure 11 IQ defects 11...

Страница 663: ...February 2013 3 17 ColorQube 9303 Family IQ 1 Image Quality Figure 12 IQ defects 12...

Страница 664: ...February 2013 3 18 ColorQube 9303 Family IQ 1 Image Quality Figure 13 IQ defects 13...

Страница 707: ...February 2013 3 61 ColorQube 9303 Family IQ 15 Image Quality Figure 4 Corrupt image data Figure 5 Service test pattern...

Страница 728: ...February 2013 3 82 ColorQube 9303 Family IQ 29 IQ 30 Image Quality...

Страница 736: ...February 2013 3 90 ColorQube 9303 Family TP 15 Image Quality Figure 2 Media path test pages...

Страница 752: ...February 2013 3 106 ColorQube 9303 Family TP 26 Image Quality Figure 1 Print head uniformity colour bands test page...

Страница 758: ...February 2013 3 112 ColorQube 9303 Family IQS 7 IQS 8 Image Quality...

Страница 778: ...February 2013 4 20 ColorQube 9303 Family REP 1 9 Repairs Adjustments...

Страница 794: ...February 2013 4 36 ColorQube 9303 Family REP 3 10 Repairs Adjustments...

Страница 1144: ...February 2013 4 386 ColorQube 9303 Family REP 94 1 Repairs Adjustments...

Страница 1176: ...February 2013 4 418 ColorQube 9303 Family ADJ 62 3 ADJ 62 4 Repairs Adjustments...

Страница 1182: ...February 2013 4 424 ColorQube 9303 Family ADJ 75 3 Repairs Adjustments...

Страница 1184: ...February 2013 4 426 ColorQube 9303 Family ADJ 82 1 Repairs Adjustments...

Страница 1186: ...February 2013 4 428 ColorQube 9303 Family ADJ 91 1 Repairs Adjustments...

Страница 1348: ...February 2013 6 56 ColorQube 9303 Family GP 19 General Procedures Information Figure 1 SIM card matrix...

Страница 1378: ...February 2013 6 86 ColorQube 9303 Family GP 29 General Procedures Information Document Handler DADH Figure 4 DADH Sensor Map...

Страница 1380: ...February 2013 6 88 ColorQube 9303 Family GP 29 General Procedures Information High Volume Finisher HVF Figure 6 HVF Sensor Map...

Страница 1552: ...February 2013 6 260 ColorQube 9303 Family dC140 General Procedures Information...

Страница 1576: ...February 2013 6 284 ColorQube 9303 Family dC640 General Procedures Information...

Страница 1578: ...February 2013 6 286 ColorQube 9303 Family dC708 dC715 General Procedures Information...

Страница 1600: ...February 2013 7 2 ColorQube 9303 Family Wiring Data...

Страница 1696: ...February 2013 8 2 ColorQube 9303 Family Principles of Operation...

Страница 1718: ...February 2013 8 24 ColorQube 9303 Family Principles of Operation Figure 1 Sensors in the media path...

Страница 1808: ...February 2013 8 114 ColorQube 9303 Family Principles of Operation...

Страница 1809: ...XEROX EUROPE...

Страница 1810: ...XEROX EUROPE...

Страница 1811: ...XEROX EUROPE...

Страница 1812: ...XEROX EUROPE...