February 2013

8-48

ColorQube® 9303 Family

Principles of Operation

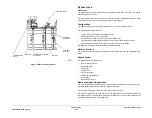

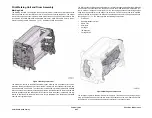

The inner two fingers are approximately 56 mm apart for registering thinner media fed by the

bypass and the outer two fingers are approximately 250 mm apart for registering the wider

media fed by the bypass.

The registration gate is positioned such that when the stack is registered:

•

the stacks lead edge will be at the base of the ramp between the nudger and the feed nip,

•

the nudger will be above the stack ready to lower and feed, and

•

the media present sensor flag will be resting on the top of the stack indicating that media

is present.

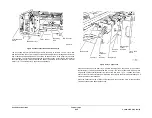

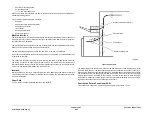

Media Size Detection

The media size detection in the bypass tray is achieved using the width of the stack indicated

by the position of the media guides.

The customer is required to set the media guides to the front and rear edges of the stack to

enable accurate media width sensing.The user must correctly adjust the guide position, as

there is no alternative mechanism for sensing the media width in the bypass tray.

The media guides move synchronously when the customer moves either guide due to a double

rack and pinion mechanism. This ensures that the rack connected to the rear guide is always in

the same place for any specific media width.

The bypass tray features a potentiometer that has its follower sprung loaded against a ramp

profile in the rear rack. As the guides are moved further apart the voltage output from the

potentiometer decreases and when the guides are moved closer together the voltage output

from the potentiometer increases.

Also housed in the bypass tray is an opto-interrupt sensor called the media width sensor. The

activation flag of this sensor is part of the rear rack. The flag in the rack has three sections to it

giving a total of 7 regions.

There are 3 regions with a voltage high response and 4 regions with a voltage low response.

The combination of the potentiometer output voltage and the state of the media width sensor

indicates to the bypass tray software which width region the rear guide is in.

Each region has a defined maximum and minimum stack width that could be in the tray. This

information is then passed onto the IME code where the user is required to confirm the media

size in the tray.

As the width sensing is market differentiated, the default media size that will be presented to

the user for any given width region will depend on the worldwide location of the machine.

Table 1

covers each region’s width boundaries, default media by market and other media.

The media size in the cross process direction is detected using the potentiometer and flag sen-

sor, attached to the paper width guides. The user is asked to confirm the detected width size

via the UI or to enter a custom size. The size in the process direction is measured when the

edge of the paper activates the paper path timing sensor #16.

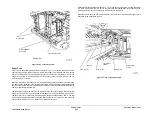

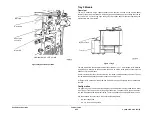

Nudger and Registration gate Operation

The nudger is lifted and lowered via a cam mechanism that is driven when the stepper motor is

reversed. Rotating the motor in reverse does not drive either the feed or the nudger roll due to

the one-way clutches on the feed shaft. The cam can only be driven in one direction by virtue

of a one way bearing housed in one of the gears in the gear train driving the cam. There are 2

‘V’ profiles on the cam surface that interact with the nudger follower and an additional spring

loaded locking lever. These enable the following functionality;

1.

When the nudger follower is in either ‘V’ it prevents the nudger from lowering onto the

stack

2.

When the additional locking lever is in a ‘V’ it prevents the cam rotating and lifting the

nudger during feeding, or affecting the nudger load.

3.

Enables a large stop position window for all functional positions as the ‘Vs’ enable the

mechanism to self centre when stopped (the self centring also provides positional robust-

ness to any system vibrations should they occur)

The registration gate in its media loading position has its’ four fingers vertical in the paper path

at the base of the ramp between the nudger and the separation nip. The reg gate hard stop is

provided by a sprung loaded locking lever that prevents the rotation of the reg gate at its cam

follower. As the cam is rotated it first lifts the locking lever, thus removing the reg gate hard

stop, and then rotates the reg gate so its’ fingers retreat out of the paper path. The cam is

designed so that the nudger is not lowered until the reg gate is completely out of the paper path

and the reg gate is not raised until the nudger has been lifted off the stack. The reg gate returns

to its hard stopped position using a return spring. The forces have been balanced to ensure

that the reg gate spring will always overcome the locking lever spring forces. This ensures that

when media is removed from the bypass tray the reg gate will always return to its media load

locked position.

Table 1 Region width boundaries

Width Region

Region width

(mm)

US default

EU default

Other media sizes

in region

Min

Max

Region 1

100

126

ENV US#10 SEF

Env dl SEF

-

Region 2

122

170

Statement SEF

A5 SEF

Env C5 SEF, Env 6

x 9 SEF

Region 3

166

206

Executive

-

-

Region 4

202

256

Letter SEF

A4 SEF

Env C4 SEF, Env 9

x 12 SEF

Region 5

252

290

Letter LEF

-

Tabloid SEF

Region 6

286

314

Tabloid extra SEF

A4 LEF

A3 SEF

Region 7

310

322

-

SRA3 SEF

-

Содержание ColorQube 9303 Series

Страница 1: ...Xerox ColorQube 9303 Family Service Manual 708P90290 February 2013...

Страница 4: ...February 2013 ii ColorQube 9303 Family Introduction...

Страница 18: ...February 2013 1 2 ColorQube 9303 Family Service Call Procedures...

Страница 92: ...February 2013 2 68 ColorQube 9303 Family 05F Status Indicator RAPs...

Страница 104: ...February 2013 2 80 ColorQube 9303 Family 12 701 00 65 Status Indicator RAPs...

Страница 200: ...February 2013 2 176 ColorQube 9303 Family 12N 171 Status Indicator RAPs...

Страница 292: ...February 2013 2 268 ColorQube 9303 Family 16D Status Indicator RAPs...

Страница 320: ...February 2013 2 296 ColorQube 9303 Family 42 504 00 42 505 00 Status Indicator RAPs...

Страница 500: ...February 2013 2 476 ColorQube 9303 Family 94B Status Indicator RAPs...

Страница 648: ...February 2013 3 2 ColorQube 9303 Family Image Quality...

Страница 653: ...February 2013 3 7 ColorQube 9303 Family IQ 1 Image Quality Figure 1 IQ defects 1...

Страница 654: ...February 2013 3 8 ColorQube 9303 Family IQ 1 Image Quality Figure 2 IQ defects 2...

Страница 655: ...February 2013 3 9 ColorQube 9303 Family IQ 1 Image Quality Figure 3 IQ defects 3...

Страница 656: ...February 2013 3 10 ColorQube 9303 Family IQ 1 Image Quality Figure 4 IQ defects 4...

Страница 657: ...February 2013 3 11 ColorQube 9303 Family IQ 1 Image Quality Figure 5 IQ defects 5...

Страница 658: ...February 2013 3 12 ColorQube 9303 Family IQ 1 Image Quality Figure 6 IQ defects 6...

Страница 659: ...February 2013 3 13 ColorQube 9303 Family IQ 1 Image Quality Figure 7 IQ defects 7 Figure 8 IQ defects 8...

Страница 660: ...February 2013 3 14 ColorQube 9303 Family IQ 1 Image Quality Figure 9 IQ defects 9...

Страница 661: ...February 2013 3 15 ColorQube 9303 Family IQ 1 Image Quality Figure 10 IQ defects 10...

Страница 662: ...February 2013 3 16 ColorQube 9303 Family IQ 1 Image Quality Figure 11 IQ defects 11...

Страница 663: ...February 2013 3 17 ColorQube 9303 Family IQ 1 Image Quality Figure 12 IQ defects 12...

Страница 664: ...February 2013 3 18 ColorQube 9303 Family IQ 1 Image Quality Figure 13 IQ defects 13...

Страница 707: ...February 2013 3 61 ColorQube 9303 Family IQ 15 Image Quality Figure 4 Corrupt image data Figure 5 Service test pattern...

Страница 728: ...February 2013 3 82 ColorQube 9303 Family IQ 29 IQ 30 Image Quality...

Страница 736: ...February 2013 3 90 ColorQube 9303 Family TP 15 Image Quality Figure 2 Media path test pages...

Страница 752: ...February 2013 3 106 ColorQube 9303 Family TP 26 Image Quality Figure 1 Print head uniformity colour bands test page...

Страница 758: ...February 2013 3 112 ColorQube 9303 Family IQS 7 IQS 8 Image Quality...

Страница 778: ...February 2013 4 20 ColorQube 9303 Family REP 1 9 Repairs Adjustments...

Страница 794: ...February 2013 4 36 ColorQube 9303 Family REP 3 10 Repairs Adjustments...

Страница 1144: ...February 2013 4 386 ColorQube 9303 Family REP 94 1 Repairs Adjustments...

Страница 1176: ...February 2013 4 418 ColorQube 9303 Family ADJ 62 3 ADJ 62 4 Repairs Adjustments...

Страница 1182: ...February 2013 4 424 ColorQube 9303 Family ADJ 75 3 Repairs Adjustments...

Страница 1184: ...February 2013 4 426 ColorQube 9303 Family ADJ 82 1 Repairs Adjustments...

Страница 1186: ...February 2013 4 428 ColorQube 9303 Family ADJ 91 1 Repairs Adjustments...

Страница 1348: ...February 2013 6 56 ColorQube 9303 Family GP 19 General Procedures Information Figure 1 SIM card matrix...

Страница 1378: ...February 2013 6 86 ColorQube 9303 Family GP 29 General Procedures Information Document Handler DADH Figure 4 DADH Sensor Map...

Страница 1380: ...February 2013 6 88 ColorQube 9303 Family GP 29 General Procedures Information High Volume Finisher HVF Figure 6 HVF Sensor Map...

Страница 1552: ...February 2013 6 260 ColorQube 9303 Family dC140 General Procedures Information...

Страница 1576: ...February 2013 6 284 ColorQube 9303 Family dC640 General Procedures Information...

Страница 1578: ...February 2013 6 286 ColorQube 9303 Family dC708 dC715 General Procedures Information...

Страница 1600: ...February 2013 7 2 ColorQube 9303 Family Wiring Data...

Страница 1696: ...February 2013 8 2 ColorQube 9303 Family Principles of Operation...

Страница 1718: ...February 2013 8 24 ColorQube 9303 Family Principles of Operation Figure 1 Sensors in the media path...

Страница 1808: ...February 2013 8 114 ColorQube 9303 Family Principles of Operation...

Страница 1809: ...XEROX EUROPE...

Страница 1810: ...XEROX EUROPE...

Страница 1811: ...XEROX EUROPE...

Страница 1812: ...XEROX EUROPE...