•

•

•

•

•

•

•

•

•

•

•

-

-

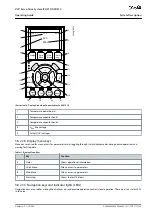

3.2.4.2 Brake (Optional)

The optional mechanical holding brake is designed as a single-disc brake. The emergency stop function can be initiated at most

once every 3 minutes and up to 2000 times in total, depending on the load.

The effective holding torque is:

Size 1: 2.5 Nm

Size 2: 5.3 Nm

Size 3: 14.5 Nm

Size 4: 25 Nm

The brake operates as a holding brake according to the fail-safe principle

closed when no current

. It is powered from the 24 V DC

auxiliary supply. This enables low-backlash load holding when no current is present.

Electrical data: Power consumption:

Size 1: 1.5 W

Size 2: 1.8 W

Size 3: 3.5 W

Size 4: 5 W

N O T I C E

Do not misuse the holding brake as a working brake because this causes increased wear, resulting in premature failure.

Using ISD 510 servo drives with brakes can reduce the number of drives allowed, depending on the total length of each

hybrid line.

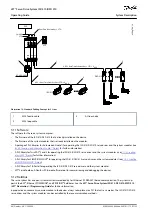

3.2.4.3 Cooling

The ISD 510 servo drives are self-cooling. Cooling (heat dispersal) is primarily via the flange, with a small amount dispersed by the

housing.

3.2.4.4 Thermal Protection

Thermal sensors monitor the maximum allowable temperature of the motor winding and switch the motor off if the limit of 150 °C is

exceeded. Thermal sensors are also present in the drive to protect the electronics against overtemperature. An error message is sent

via Real-Time Ethernet to the higher-level PLC and is also shown on the LCP.

3.2.4.5 Built-in Feedback Devices

The built-in feedback device measures the rotor position. There are 3 feedback variants available:

Resolver

BiSS-B 17 bit single-turn encoder

BiSS-B 17 bit multi-turn encoder

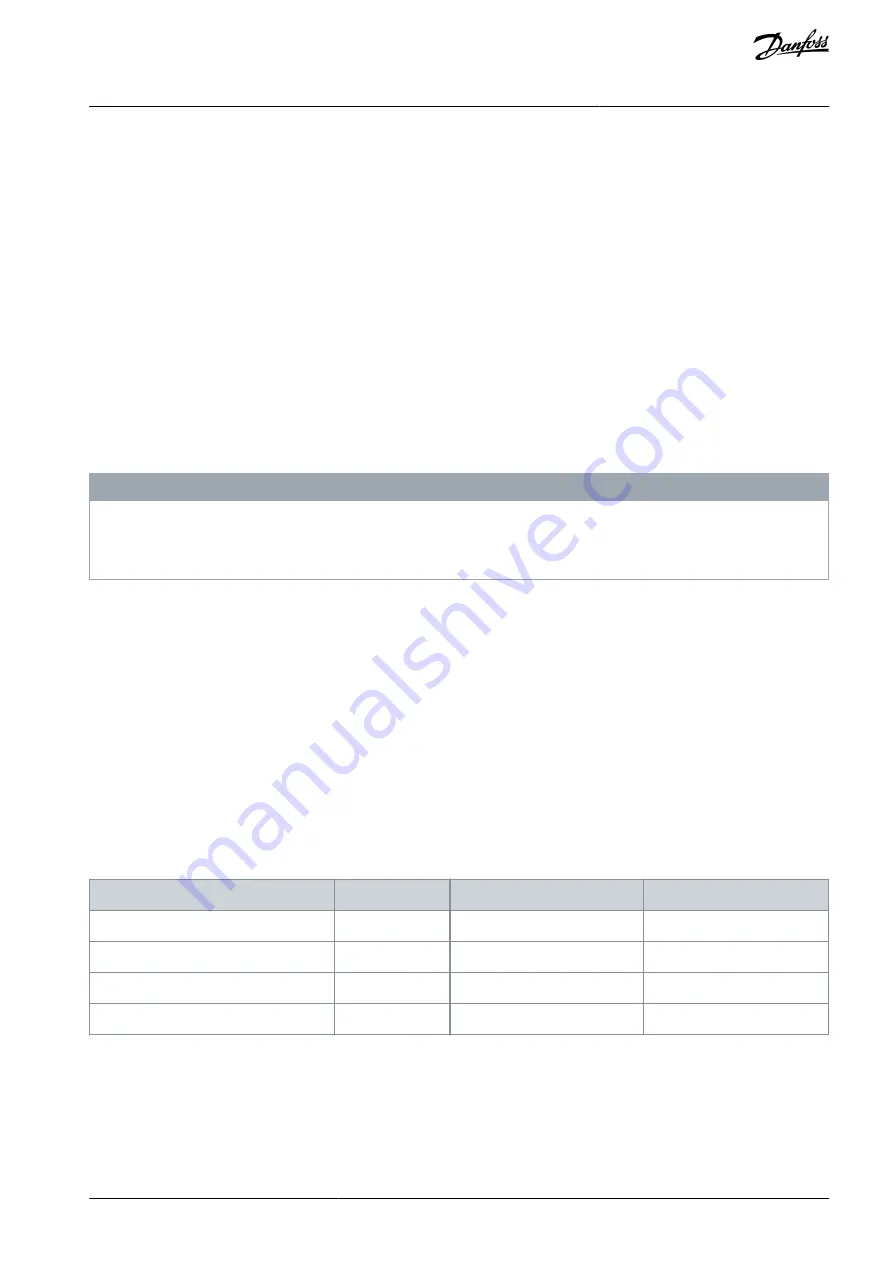

Data/type

Resolver

Single-turn encoder

Multi-turn encoder

Signal

Sin/cos

BiSS-B

BiSS-B

Accuracy

±10 arcmin

±1.6 arcmin

±1.6 arcmin

Resolution

14 bit

17 bit

17 bit

Maximum number of turns

–

–

4096 (12 bit)

3.2.5 Drive Components

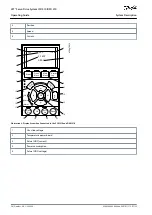

3.2.5.1 Connectors on the ISD 510 Servo Drives

This section details all possible connections for the standard and advanced servo drive.

There are 5 connectors on the ISD 510 servo drives.

AQ262449648484en-000101 / 175R1135 | 29

Danfoss A/S © 2020.08

System Description

VLT® Servo Drive System ISD 510/DSD 510

Operating Guide