-

-

10 Maintenance, Decomissioning, and Disposal

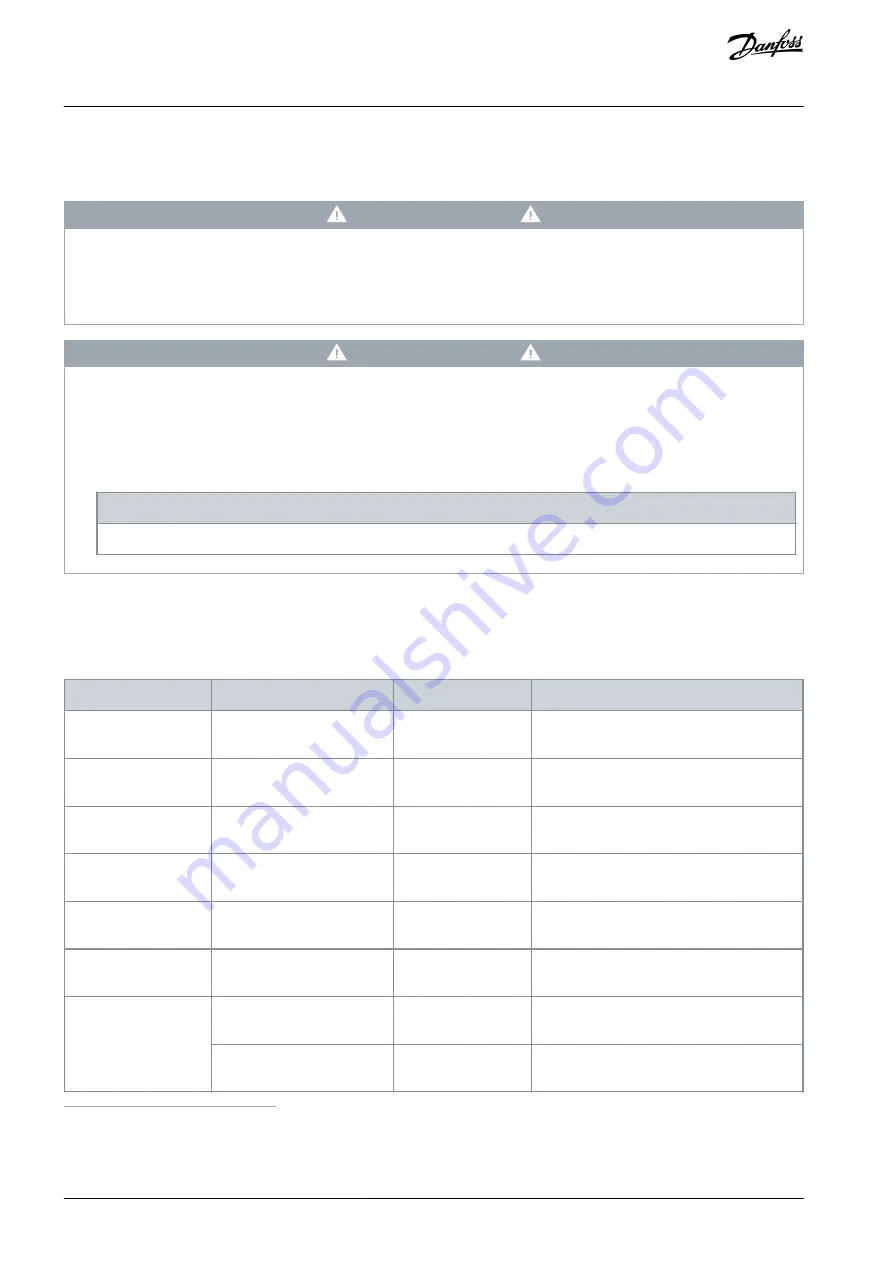

10.1 Warnings

W A R N I N G

HIGH VOLTAGE

Potentially lethal voltage is present on the connectors that may lead to death or serious injury.

Before working on the power or signal connectors (disconnecting or connecting the cable), or performing any maintenance

work, disconnect the Power Supply Module (PSM 510) from the mains and wait for the discharge time to elapse.

W A R N I N G

DISCHARGE TIME

The servo system contains DC-link capacitors that remain charged for some time after the mains supply is switched off at the

Power Supply Module (PSM 510). Failure to wait the specified time after power has been removed before performing service or

repair work could result in death or serious injury.

To avoid electrical shock, fully disconnect the Power Supply Module (PSM 510) from the mains and wait for the capacitors to

fully discharge before carrying out any maintenance or repair work on the servo system or its components.

Minimum waiting time (minutes)

15

10.2 Maintenance Tasks

The ISD 510/DSD 510 servo drives are largely maintenance free. Only the shaft seal on the ISD 510 (if used) is subject to wear. The

maintenance tasks must be performed by qualified personnel. No other tasks are required.

Table 120: Overview of Maintenance Tasks

Component

Maintenance task

Maintenance interval Instruction

Servo drive

Carry out a visual inspection.

Every 6 months

Check for any abnormalities on the surface of

the servo drive.

Shaft seal on the ISD

510

Check the condition and

check for leakage.

Every 6 months

(1)

If damaged, replace the shaft seal.

Flange connection on

the ISD 510

Measure the resistance.

Every 12 months.

Measure the resistance of the flange connec-

tion on the ISD 510.

Hybrid cable

Check for damage and wear.

Every 6 months

If damaged or worn: Replace the hybrid ca-

ble.

Mechanical holding

brake (optional)

Check the brake.

Every 6 months

Ensure that the brake can achieve the hold-

ing torque.

Functional safety

Perform a system power cycle

and check the STO function.

Every 12 months

Activate STO and check the status with the

PLC.

System modules

Check the fan.

Every 12 months

Check that the fan can turn and remove any

dust or dirt.

Carry out a visual inspection

Every 6 months

Check for any abnormalities on the surface of

the module.

1

A shorter interval may be necessary depending on the application. Contact Danfoss for more information.

AQ262449648484en-000101 / 175R1135

176 | Danfoss A/S © 2020.08

Maintenance, Decomissioning, and

Disposal

VLT® Servo Drive System ISD 510/DSD 510

Operating Guide