Configuration

5-38

7SA522 Manual

C53000-G1176-C119-2

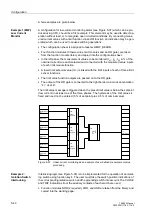

Figure 5-34

Connector

Events

Events (SP_Ev, DP_Ev) are not suitable for processing in CFC, and should therefore

not be used as input signals.

Consistency check

In addition to the sample configuration chart 1, other configuration sheets may exist.

The contents of any particular configuration sheet is compiled by DIGSI

®

4 into a pro-

gram and processed by the protective device. For CFC charts developed by the user,

syntactic correctness can be verified by clicking the menu command

&KDUW

, and then

&KHFN&RQVLVWHQF\

. The consistency check will determine if the modules violate

conventions of various task levels, or any of the space limitations described below.

Check of functional correctness must be performed manually.

The completed CFC chart can be saved via menu item

&KDUW

, and

&ORVH

. Likewise,

the CFC chart may be reopened and edited by clicking on

&KDUW

, selecting the appro-

priate chart, and clicking on

2SHQ

.

Please note that certain limits and restrictions exist due to the available memory and

processing time required. For each of the four PLC task levels there is only a finite

processing time available within the processor system. Each module, each input to a

module (whether connected or not), each link generated from the border columns de-

mands a specific amount of processing time. The sum total of the individual process-

ing times in a task level may not exceed the defined maximum processing time for this

level.

The processing time is measured in so called TICKS. In the 7SA522 the following

maximum TICKS are permitted in the various task levels:

In the following table, the amount of TICKS required by the individual elements of a

CFC chart is shown. A generic module refers to a module for which the number of in-

puts can be changed. Typical examples are the logic modules

AND

,

NAND

,

OR

,

NOR

.

Connector

Table 5-8

Maximum number of TICKS in the task levels of 7SA522

Run-Time Level

Limits in TICKS

0:B%($5%

(Measured value processing)

10000

3/&B%($5%

(Slow PLC processing)

1900

3/&B%($5%

(Fast PLC processing)

200

6)6B%($5%

(

Interlocking)

10000

Summary of Contents for siprotec 7SA522

Page 20: ...7SA522 Manual C53000 G1176 C119 2 ...

Page 64: ...7SA522 Manual C53000 G1176 C119 2 ...

Page 89: ...SIPROTEC 4 Devices 4 25 7SA522 Manual C53000 G1176 C119 2 Figure 4 20 CFC Logic example ...

Page 408: ...7SA522 Manual C53000 G1176 C119 2 ...

Page 456: ...7SA522 Manual C53000 G1176 C119 2 ...

Page 516: ...7SA522 Manual C53000 G1176 C119 2 ...

Page 620: ...Appendix B 48 ...