Step 2: Performing a zero point adjustment

The second step in the troubleshooting procedure is to zero point adjust the device. For further

information on zero point adjustment, see Commissioning (Page 91).

Step 3: Calculating the measurement error

The result of the zero point adjustment will show you if the zero point was set under good and

stable conditions.

The lower the obtained value of the parameter Zero Point Standard Deviation, the lower is the

achievable measuring error. For a well-installed flowmeter, the Zero Point Standard Deviation

corresponds to the specified zero point stability for the sensor size, see Performance

(Page 215).

The parameter Zero Point Standard Deviation is located in the Maintenance & Diagnostics

menu in the SIMATIC PDM.

Calculating the measurement error

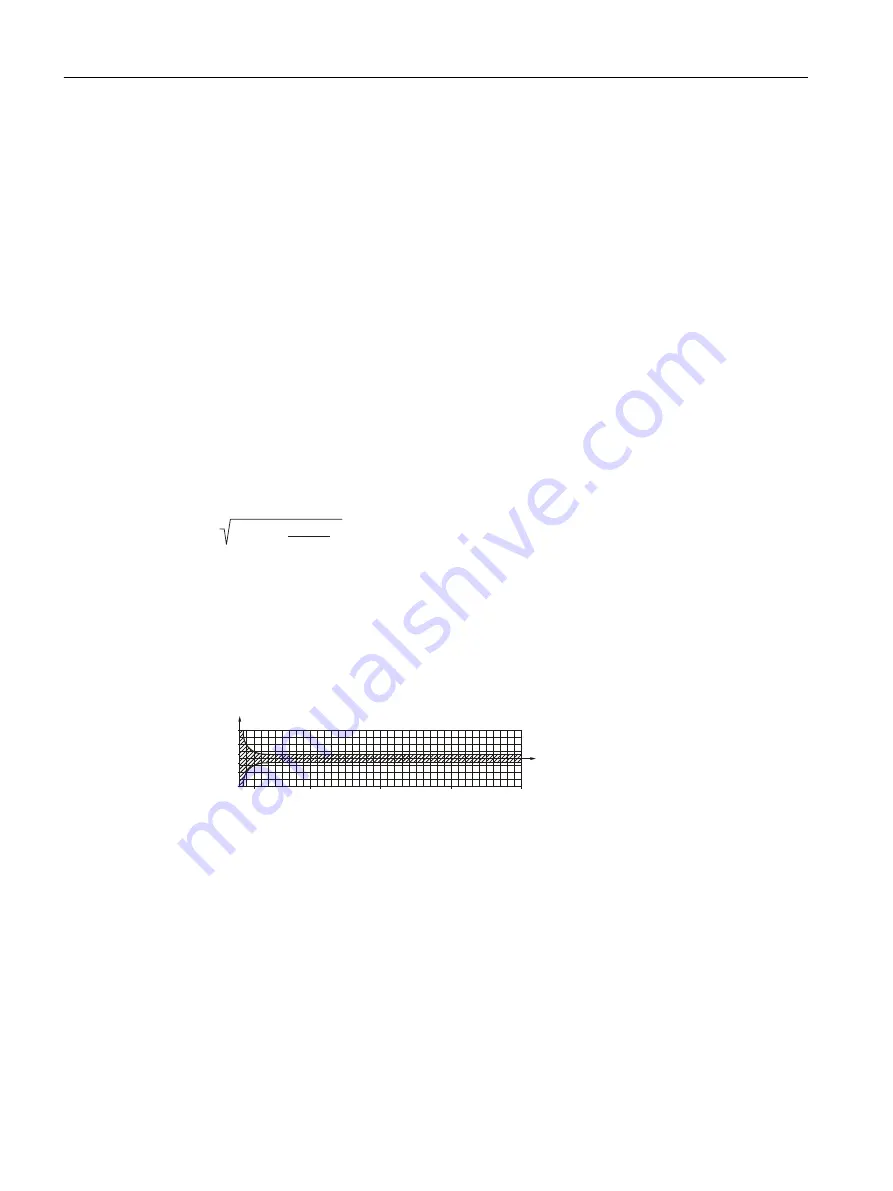

● The error curve is plotted from the formula:

E = ± (Cal)

2

+

z x 100

qm

( )

2

E

= Error [%]

Z

= Zero point [kg/h]

qm = Mass flow [kg/h]

Cal. = Calibrated flow accuracy: 0.10 or 0.15

FSO (sensors

max. flow rate)

Error in % of actual mass flow rate with 95% confidence

(probability)

Actual mass

flow rate

-1.0

-0.5

1.0

0.5

0.15

-0.15

50%

25%

5%

75%

100%

Table 10-2

Reference conditions for flow calibrations (ISO 9104 and DIN/EN 29104)

Flow conditions Fully developed flow profile

Temperature,

medium

20 °C ± 2 °C (68 °F ± 3.6 °F)

Temperature,

ambient

20 °C ± 2 °C (68 °F ± 3.6 °F)

Liquid pressure 2 ± 1 bar

Density

0.997 g/cm3

Brix

40 °Brix

Diagnosing and troubleshooting

10.3 Operation troubleshooting

MASS 2100 & FC300 (FCT030)

210

Operating Instructions, 06/2017, A5E39789040-AA