Chapter

Ⅳ

Tool Nose Radius Compensation

175

Ⅰ

Programming

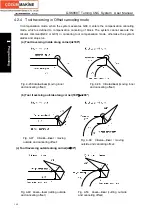

Fig.4-66 inner corner machining less than tool nose radius

z

Machining concave less than tool nose diameter

There is an excessive cutting when the tool nose center path is opposite to program path caused

by tool nose radius compensation. At the moment, the tool stops and the system alarms No.257 when

starting the previous block or chamfer moving.

Tool nose center path

Display alarm and stop working

Overcutting

Programmed path

Fig. 4-67 machining a grooving less than tool nose radius

z

Machining a inner sidestep less than 90°

When the system machines a inner sidestep less than or equal to

90°

and the machining

path length is less than the tool nose radius, there will be the too much undercut and No. 260

alarms. At the moment, No.5008 Bit6 (CNS) sets whether the system alarms in the condition.

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...