GSK988T Turning CNC System User Manual

156

Ⅰ

Programming

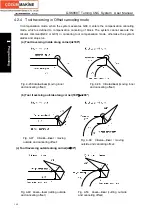

distances from the standard point to the tool nose radius center than from the standard point to the

imaginary tool nose, and so set the tool offset value by measuring distance from the standard point to

the imaginary tool nose(tool nose direction of T3).

Fig. 4-10 Tool offset value of tool post center as benchmark

4.1.4 G40/G41/G42 command function

Taking the previous and the current position increment as the programmed path can cancel the

tool compensation mode, and its direction is the compensation direction of the previous. When the

system specifies

(

I, J

)

,

(

I, K

)

or

(

J, K

)

, the vector defined by it can replace the current position

increment to execute the count.

Command format:

X Z T ;

In machining workpiece, the tool offset cannot easily compensate the precise workpiece because

of the tool nose circle degree but the tool nose radius compensation function can automatically

compensate the error.

G40 Xp Yp Zp I J K

G40

G41

G42

G00

G01

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...