Chapter

Ⅱ

G Commands

53

Ⅰ

Programming

Note: The system has created the above coordinate system after the 1

st

reference position return is

executed. The coordinate system is created after the system is turned on with the absolute

position encoder.

2.13.1 Selecting machine coordinate system position G53

A particular on the machine as the machining reference is called as the machine zero which is

taken as the origin of the coordinate system is called as the machine coordinate system. After the

system is turned on, executing the manual reference position return sets the machine coordinate

system which keeps till the system is turned off.

Command format:

G53 IP ;

Command function

: when the position of the machine coordinate system is commanded, the

tool moves the position at the rapid traverse speed. Omitting one axis means the

axis does not move; when the system only specifies G53 without specifying the

positions of any axes, the system does not execute the motion.

Command explanation:

G53 is non-modal;

IP_: the absolute coordinate value for each axis in the machine

coordinate system must be specified by the absolute value.

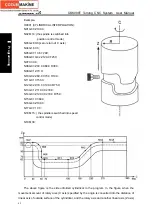

As the following figure: the specified axis rapidly moves from A (20,

20) in the current workpiece coordinate system to B (-8, -10) in the

machine coordinate system.

REF

Reference

position.

M0

Origin of machine coordinate system is a fixed point on the machine, No. 1240

value confirms the relative position of the reference position and the machine

origin.

M2

The

2

nd

reference position, No.1214 set the 2

nd

reference position position in the

machine coordinate system.

EXT

The outer origin offset can be set by No. 1220 or in the coordinate setting

window.

G50

The offset set by G50 is 0 when the system is turned on.

G54, 59

The offset of the workpiece coordinate system is set by No. 1221, No. 1226, and

is also set in the coordinate window.

W0-54,

W0-59

Origin of the workpice coordinate system.

G52

The offset of the local coordinate system is 0 when the system is switched on. All

workpiece coordinate systems share, i.e. the local coordinate system offset set in

one workpiece coordinate system can exist in other workpiece coordinate

system.

L0

Origin of the local coordinate system.

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...