Chapter

Ⅱ

G Commands

71

Ⅰ

Programming

G71 P80 Q120 U0.5 W0.2

;

(

roughing a---e

,

X machining allowance 0.5mm , Z 0.2mm

)

N80 G00 X40 S1200

;

(

Positioning

)

G01 Z-30 F100

;

(

a

→

b

)

X60 W-30

;

(

b

→

c

)

a

→

b

→

c

→

d

→

e blocks for finishing path

W-20

;

(

c

→

d

)

N120 X100 W-10

;

(

d

→

e

)

G70 P80 Q120

;

(

a---e blocks for finishing path

)

M30

;

(

End of block

)

G71 supports continuous grooving machining:

Direction of the shape in the 2

nd

axis of the level (X axis in ZX level) is not necessary to

monotonous rise or fall, and there may be up to 10 groovings, which is shown below:

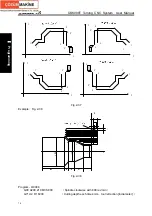

Fig. 2-39

But, external contour along Z must mononously rise or fall, and the following contour cannot be

machined:

Fig. 2-40

The first tool must be vertical: the machining can be executed when the shape along Z changes

mononously, which is shown below:

Fig. 2-41

The tool retraction should be executed after turning, and the retraction amount is

specified by R (e) or No 5133, which is shown below:

Monontone change is not observed

along the Z axis

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...