GSK988T Turning CNC System User Manual

56

Ⅰ

Programming

G55 workpiece coordinate system 2

;

G56 workpiece coordinate system 3

;

G57 workpiece coordinate system 4

;

G58 workpiece coordinate system 5

;

G59 workpiece coordinate system 6

;

Command explanation: G54

~

G59 are modal.

Note 1: The workpiece is created after the system is turned on and executes the reference position

return. When the system is turned on, it automatically selects G54 as the current workpiece

coordinate system;

Note 2: G54-G59 describing the 6 workpiece coordinate systems can change their positions by the

external workpiece zero offset value or workpiece zero offset value, and their relationship is

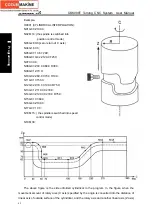

as Fig. 2-22;

Fig. 2-23

Note 3: Use the following method to change:

1

)

MDI input changes the workpiece coordinate system zero;

2

)

Use G50 to move the workpiece coordinate system;

Specifying G50 IP_ makes the workpiece coordinate system

(

G54

~

G59

)

to set a new workpiece

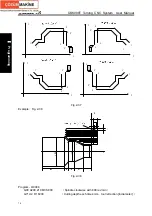

coordinate system where the current tool position is consistent with the specified coordinates.

When G50 specifies the relative value, the value adding the previous tool position coordinate

value creates a new coordinate system, but the tool position does not change but the coordinate

system executes the offset as Fig. 2-23:

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...