Chapter

Ⅱ

G Commands

63

Ⅰ

Programming

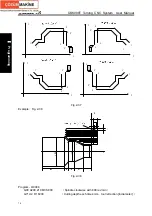

Example: Fig. 2-29, rod

Φ

125×110

Fig.2-31

Program

:

Program : O0002;

M3 S300 G0 X130 Z3;

G90 X120 Z-110 F200; (A

→

D, cut

Φ

120)

X110 Z-30;

X100;

X90;

X80;

X70;

X60;

G0 X120 Z-30;

G90 X120 Z-44 R-7.5 F150;

Z-56 R-15

Z-68 R-22.5

Z-80 R-30

M30;

2.14.2 Radial cutting cycle G94

Command function:

From starting point,

the cutting cycle of cylindrical surface or taper

surface is completed by radial feeding(X) and axial (Z or X and Z)

cutting.

Command format:

G94 X(U) __ Z(W) __ F__; (face cutting)

G94 X(U) __ Z(W) __ R__ F__; (taper face cutting)

Command specifications:

G94 is modal;

X_,Z_

Coordinate of cutting end point(C point in the figure below)in the direction of

the bottom side

U_,W_ Movement to cutting end point (C point in the figure below)in the direction of

bottom side

F_ Cutting

feedrate

R_

Taper Taper

(

radius value, with direction, range referred to the table below

(

A

→

B

,

6 times cutting cycle

Φ

60, increment of 10mm

)

(

B

→

C

,

4 times taper cutting

)

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...