GSK988T Turning CNC System User Manual

52

Ⅰ

Programming

coordinate system is changed;

Note 5: Each axis separately moves at the rapid traverse speed from the starting point through the middle

point to the reference position, i.e. G00 mode.

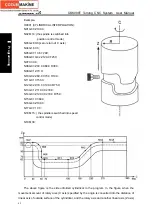

2.13 Related Function of Coordinate System

The tool position is expressed with the coordinate value of the coordinate system, the

coordinate value is specified by the programmed axis. GSK988T system has three kinds of

coordinate system:

1. machine coordinate system

2. workpiece coordinate system

3. local coordinate system

Fig.2-19 describes the relationship of the three coordinate systems:

REF

M0

EXT

G50

G54

G59

G52

G52

L0

L0

W0-54

W0-59

M2

Fig. 2-12

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...