Chapter

Ⅱ

G Commands

57

Ⅰ

Programming

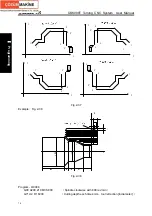

Fig. 2-24

Note 4: The coordinate offset value created by G50 adds to the one of all workpiece zero to make ensure

that all workpiece coordinate systems offset the same value as Fig. 3-21:

Fig. 2-25

Note 5: The workpiece zero offset value of G54

~

G59 workpiece coordinate system can be set in the

parameters and input in the coordinate setting window;

Note 6: When the system is turned on, it defaults G54 as the current workpiece coordinate system; after

the system executes the reference position return, it creates the coordinate system, uses G55

~

G59 to switch to other workpiece coordinate system; when the system resets, No.1201 Bit 7(WZR)

determines whether the system returns to G54 workpiece coordinate system; when No. 3402 Bit

6(CLR) is set to 1, the modal returns to G54.

2.13.4 Local coordinate system setting G52

To be convenient to programming, the sub-coordinate system to set the workpiece

coordinate system is called the local coordinate system.

Command format:

G52 IP__; set the local coordinate system

……

G52 IP0; cancel the local coordinate system (IP0 means the absolute value

for each axis adds one zero)

Summary of Contents for 988T

Page 6: ...GSK988T Turning CNC System User Manual VI ...

Page 14: ...GSK988T Turning CNC System User Manual XIV ...

Page 15: ...Chapter 1 Programming Fundamentals 1 Ⅰ Programming Ⅰ PROGRAMMING ...

Page 16: ...GSK988T Turning CNC System User Manual 2 Ⅰ Programming ...

Page 194: ...GSK988T Turning CNC System User Manual 180 Ⅰ Programming ...

Page 195: ...Chapter Ⅰ Overview 181 Ⅱ Operation Ⅱ OPERATION ...

Page 196: ...GSK988T Turning CNC System User Manual 182 Ⅱ Operation ...

Page 217: ...Chapter Ⅲ Windows 203 Ⅱ Operation ...

Page 267: ...Chapter Ⅲ Windows 253 Ⅱ Operation Fig 3 51 Fig 3 52 ...