NOTICE

• Komatsu recommends using Komatsu genuine parts for replacement parts.

• If the machine is operated without DEF tank breather element attached, or with the element other

than Komatsu genuine parts, foreign materials may enter into DEF pump and DEF injector which

will cause failure of the machine. Never operate the machine without DEF tank breather element at-

tached, nor use the element other than Komatsu genuine parts.

• Do not flush DEF tank breather element. Flushing or regenerating of it will degrade the performance

of element, and will cause the breakage of DEF tank. Never reuse the DEF element.

• Always stop the engine and clean around DEF tank before replacing.

• After the engine is stopped, DEF system devices automatically purge DEF in DEF injector and DEF

pump and return it to DEF tank to prevent malfunction of the devices caused by freezing of DEF or

deposition of urea.

After the engine is stopped, the devices are operated for a few minutes. Replace the element after

DEF system devices stop.

• Improper assembly of DEF tank breather element may cause leakage of DEF. Replace the element in

the correct procedure.

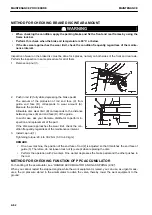

1.

Remove bolts (1) (11 pieces), and remove cover (2).

2.

Remove nut (4) of breather assembly (3) at the top of DEF

tank, then remove cover (5).

3.

Replace breather element (6) with a new one.

4.

Install cover (5) and nut (4).

5.

Install cover (2) with bolt (1).

MAINTENANCE

MAINTENANCE PROCEDURE

4-69

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...