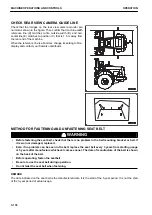

Perform the following inspection.

• Perform inspection to confirm that the fuses have no defect and their capacity is proper.

• Perform inspection to confirm that there is no disconnection or trace of short-circuiting in the electric wiring

and no damage to the coating.

• Perform inspection to confirm that there is no loose terminals, and tighten any loose parts if found.

• Always check if there is any accumulation of combustible material around the battery, and remove such

combustible material.

METHOD FOR CHECKING FUEL LEVEL, ADDING FUEL

k

k

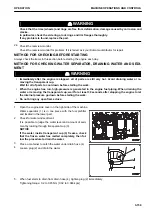

WARNING

When refilling with fuel, do not add any more fuel after the fuel filler gun has automatically stopped. If

fuel is excessively added, fuel may inflate and flow out when ambient temperature increased, and it is

dangerous.

Also, it may cause fire. If any fuel has spilled, wipe it up completely.

Fuel is highly flammable and dangerous. Never bring any open flame near fuel.

NOTICE

When restarting the engine that has stopped due to run out of fuel, all air must be sufficiently bled from

the circuit.

For the method of bleeding air, see “METHOD FOR REPLACING FUEL MAIN FILTER CARTRIDGE

(4-51)”.

Take care not to cause engine stall due to run out of fuel.

When fuel is used up, you can cut the air bleeding time by filling the fuel tank fully with fuel.

1.

Turn the starting switch to ON position (B).

2.

Check the fuel level with fuel gauge (G).

3.

After checking, turn the starting switch back to OFF posi-

tion (A).

OPERATION

MACHINE OPERATIONS AND CONTROLS

3-163

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...