1.

Apply the parking brake.

2.

Raise the work equipment to the upper end and operate

the boom control lever to HOLD position (b).

3.

Stop the engine.

4.

Turn the starting switch to ON position.

5.

Press the work equipment lock switch and unlock the work

equipment (the pilot lamp goes out).

6.

After checking safety around the machine, operate the

boom control lever to FLOAT position (d) and lower the

work equipment to a position 1 m from the ground.

7.

After the work equipment is lowered to a position 1 m from

the ground, return the boom control lever to LOWER posi-

tion and lower the work equipment gradually to the ground.

REMARK

The check must be done within 2 minutes after the engine

stops. If the engine is kept stopped, the gas pressure in

the accumulator lowers and the inspection cannot be

made.

If the work equipment stops halfway, the accumulator gas pressure may be low.

Ask your Komatsu distributor for inspection.

Replace the accumulator for every 4000 hours or every 2 years.

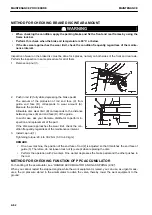

METHOD FOR CHECKING ALTERNATOR

Ask your Komatsu distributor to have the alternator checked.

If the engine is started frequently, have this inspection performed every 1000 hours.

METHOD FOR CHECKING AND ADJUSTING ENGINE VALVE CLEARANCE

Special tools are necessary for inspection and maintenance. Ask your Komatsu distributor to perform this work.

METHOD FOR CHECKING VIBRATION DAMPER

Check that there are no cracks or peeling in the outside surface of the rubber.

If any cracks or peeling are found, contact your Komatsu distributor to have the parts replaced.

METHOD FOR REPLACING KCCV FILTER ELEMENT

k

k

WARNING

After the engine has been operated, all of the parts are still very hot. Do not replace the filter element

immediately. Wait until all of parts cool down before starting the work. Always stop the engine before

starting the part replacement.

NOTICE

• Komatsu recommends using Komatsu genuine parts for replacement parts.

• If the engine is operated without the filter element, the turbocharger and aftercooler become dirty

and their performance will lower and it can cause engine problems such as overrun caused by suc-

tion of oil. Never try such practice.

• The filter element cannot be flushed. Flushing or regenerating of the filter element will degrade per-

formance of the filter. As a result, the turbocharger and aftercooler become dirty and the perform-

ance lowers or the crankcase pressure increases. Never reuse the filter element since it can cause

an engine failure.

• After the filter element is replaced, if KCCV is not assembled correctly, oil or blowby gas may leak.

Replace the filter element in the correct procedure.

MAINTENANCE

MAINTENANCE PROCEDURE

4-63

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...