1.

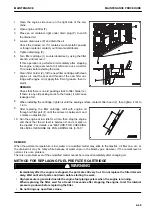

Insert the starting switch into key lock (1) and release the

lock.

2.

Pull the key and open cover (2).

REMARK

If the cover does not open easily by turning the key, push

the cover with your hand to facilitate its opening.

3.

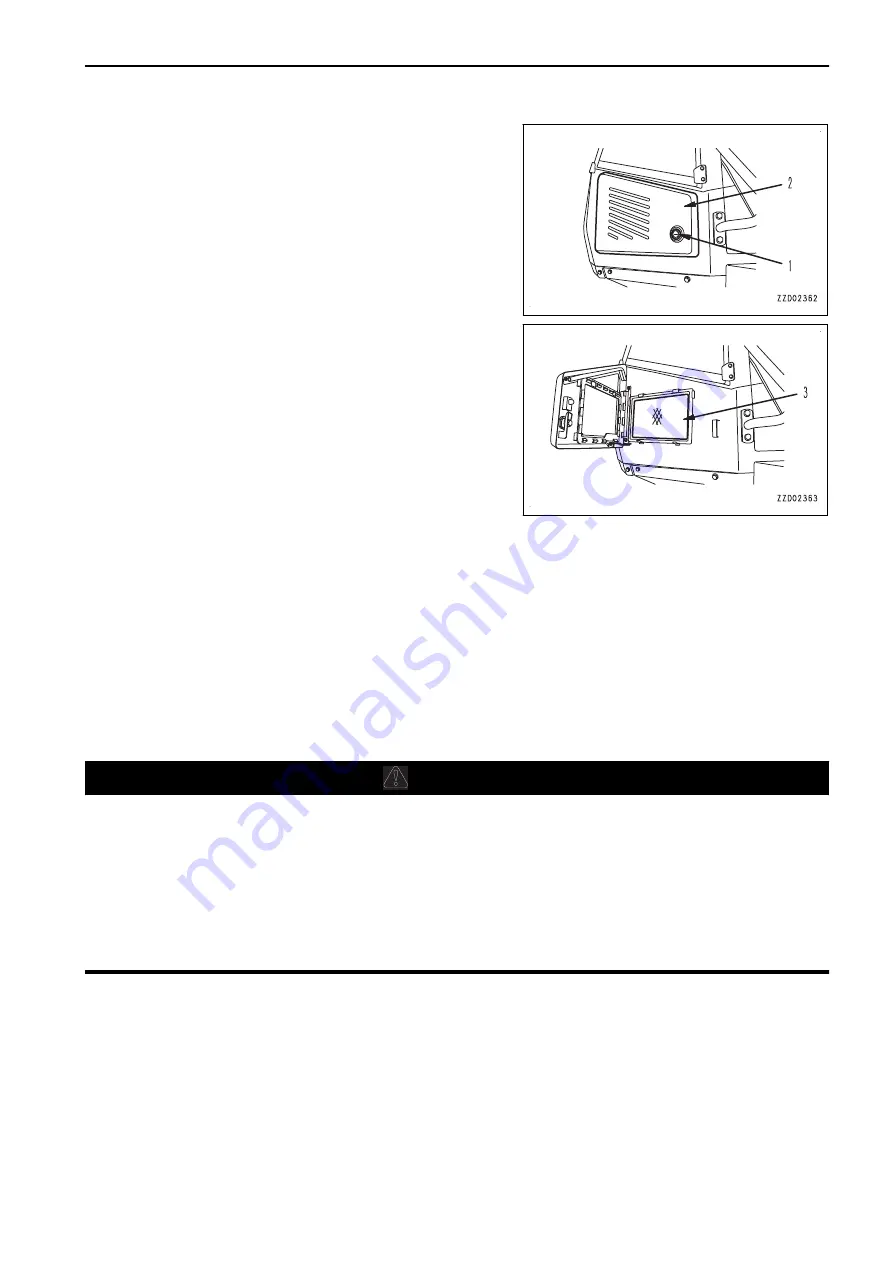

Take out filter (3) and clean it.

4.

Blow dry compressed air (0.2 MPa {2.1 kg/cm

2

} or below)

from the inside of each filter along the pleats.

Next, blow along the pleats from the outside, then blow

again from the inside.

Replace the filter with a new one when the dirt clogging

the filter cannot be removed by blowing air or every year.

5.

After cleaning, return filter (3) to its original position and

close the cover.

At this time, lock the cover with the starting key. Do not for-

get to remove the starting key.

REMARK

If the filter becomes clogged, the air flow will be reduced, and there will be a rumbling sound from the air

conditioner unit.

EVERY 250 HOURS MAINTENANCE

Maintenance for every 50 hours service should be performed at the same time.

METHOD FOR CHECKING BATTERY ELECTROLYTE LEVEL

Perform this procedure before operating the machine.

Inspect the battery electrolyte level according to the standard at least once a month.

k

k

WARNING

• Do not use the battery if the battery electrolyte level is below LOWER LEVEL line. If you do so, it will

reduce the service life of the battery. In addition, it may cause an explosion.

• The battery generates inflammable hydrogen gas and there is a danger of explosion. Do not bring

any open flame near the battery.

• Battery electrolyte is dangerous object. If it gets in your eyes or on your skin, wash it off with a

large amount of water and consult a doctor.

• Do not use a dry wipe to clean the battery. A wet wipe will prevent fire or explosion from static elec-

tricity.

NOTICE

• Do not add the electrolyte to the battery exceeding UPPER LEVEL line. If the electrolyte level is too

high, it may leak and cause damage to the paint surface or corrode other parts.

• If there is a fear that the battery water may freeze after refilling with purified water (such as a com-

mercial battery fluid), do the replenishment before the day's work on the next day.

METHOD FOR CHECKING ELECTROLYTE LEVEL FROM SIDE OF BATTERY

If it is possible to check the electrolyte level from the side of the battery, check as follows.

MAINTENANCE

MAINTENANCE PROCEDURE

4-43

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...