11. Check transmission case, axle, hydraulic tank, hoses, and joints for oil leakage.

Check for oil leakage. If any problem is found, repair the place where the oil is leaking.

12. Check brake line for oil leakage.

Check for leakage of oil or damage to the hoses and tubes. If any problem is found, repair it.

13. Check the tires, wheels, and wheel hub bolts and nuts for damaged and wear, and check the wheel hub

bolts and nuts for looseness.

Check for cracks or peeling of the tires and for cracks or wear of the wheels (side ring, rim base, lock ring).

Tighten any loose wheel hub bolts or nuts. If any problem is found, repair or replace the part.

If any valve cap is missing, install a new one.

14. Check the handrails and steps for damages and check the bolts for looseness.

If any damage is found, repair it. Tighten any loose bolts.

15. Check the gauges and monitor for problem.

Check for problem in the gauges and monitor in the operator's cab. If any problem is found, replace the

part. Clean off any dirt on the surface.

REMARK

When cleaning the stains deposited on the monitor surface such as dusts, brush them off using a clean,

soft and dry cloth.

For sticky dirt such as oil, remove it with glass cleaner for family use on the market (weakly acid to weakly

alkaline, containing no abrasive), and then finish-wipe with a clean, soft, and dry cloth.

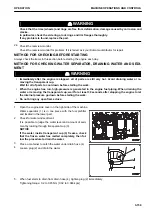

16. Check and clean the rearview mirrors

Check for damage to the rearview mirrors. If it is damaged, repair it. Clean the surfaces of the mirrors and

adjust the angle according to “METHOD FOR ADJUSTING MIRRORS (3-174)”.

17. Check and clean the camera.

When cleaning the camera, wipe off any dirt with soft cloth.

When cleaning camera, if you stand on an unstable place, or take an unstable posture, you may fall and be

injured. Put proper stepladder or step on the level and firm ground, and clean the camera in secure posture.

Check that the camera is in correct position or has no abnormality. If any problem is found, ask your Komat-

su distributor for repair.

18. Check the air cleaner mounting bolts for looseness.

Check for loose mounting bolts. If any loose bolt is found, retighten it.

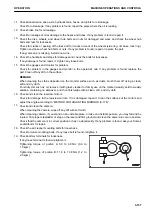

19. Check battery terminals for looseness.

If any loose terminal is found, retighten it.

Tightening torque of portion A: 5.9 to 9.8 Nm {0.6 to

1.0 kgm}

Tightening torque of portion B: 11.8 to 19.6 Nm {1.2 to

2.0 kgm}

OPERATION

MACHINE OPERATIONS AND CONTROLS

3-157

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...