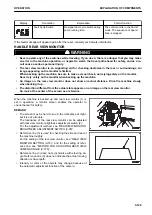

The KDPF regeneration is performed automatically. However,

the accumulated soot may not be burnt sufficiently and the fil-

tering function may not be improved under certain operating

conditions.

In that case, KDPF soot accumulation caution lamp (2) lights

up. If this lamp lights up, stop the machine in a safe place and

perform the manual stationary regeneration.

For details of the procedure, see “PROCEDURE FOR MAN-

UAL STATIONARY REGENERATION (3-133)”.

Two types of monitor display require the manual stationary re-

generation, depending on the level of urgency.

When the directional lever is turned to NEUTRAL position (N)

and the parking brake switch is turned to the “ON” position, the

manual stationary regeneration may start automatically to pro-

tect the KDPF.

NOTICE

Do not stop engine when the aftertreatment devices regeneration is activated.

If KDPF soot accumulation caution lamp (2) is displayed, be sure to perform the manual stationary re-

generation.

When stopping the engine, stop the aftertreatment devices regeneration first according to “PROCE-

DURE FOR AFTERTREATMENT DEVICES REGENERATION DISABLE SETTING (3-136)”, then keep en-

gine running at low idle for approximately 5 minutes, and stop engine.

If the work is continued while the KDPF soot accumulation caution lamp (2) stays lit in red, KDPF or the

engine can have trouble. If the KDPF soot accumulation caution lamp (2) is displayed, be sure to per-

form “manual stationary regeneration”.

If soot accumulated in the KDPF exceed the defined level

without performing the manual stationary regeneration,

the action level “L04” lights up in red, the engine output is

limited to protect the engine and KDPF system. Stop the

machine immediately and ask your Komatsu distributor.

REMARK

• Soot accumulation level (3) can be checked with the “Af-

tertreatment Devices Regeneration” screen. Press the

menu switch on the standard screen to display the “After-

treatment Devices Regeneration” screen of the user menu.

• Since the soot in the filter of KDPF can be burnt by the

high-performance catalyst and high-temperature exhaust

heat, the soot accumulation quantity may decrease even if

the regeneration is not performed, depending on the oper-

ating condition.

• Even when the soot accumulation level is low, the auto-

matic regeneration may be performed and the manual sta-

tionary regeneration may be requested to protect the system.

OPERATION

EXPLANATION OF COMPONENTS

3-131

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...