START ENGINE WITH JUMPER CABLES

k

k

WARNING

• When connecting the cables, never contact the posi-

tive (+) and negative (-) terminals.

• Always wear protective eyeglasses and rubber gloves

when starting the engine by using the jumper cable.

• Do not bring the normal machine into contact with the

failed machine.

The sparks caused near the battery could ignite the

hydrogen gas generated from the battery, so be care-

ful not to let it happen.

• Make sure that there is no mistake in the jumper cable

connections. In the last connection (to the upper

structure frame), a spark will be caused, connect the

cable to a spot as far away from the battery as possi-

ble. (However, do not connect to the work equipment

since the current does not flow well through it.)

• Do not bring the clips in contact with other clips or

with the machine when disconnecting the jumper ca-

ble.

• Never start the engine by short-circuiting the starting

motor (jump start).

NOTICE

• The starting system for this machine uses 24 V. Accordingly, the normal machine must be equipped

with a 24 V power supply.

• The sizes of the jumper cables and clips should be suitable for the battery size.

• The battery of the normal machine must be the same capacity as that of the failed machine.

• Check the cables and clips for damage or corrosion.

• Firmly connect the clips.

• Check that the lock levers and parking brake levers (if equipped) of both machine are in LOCK posi-

tion.

• Check that each lever is in NEUTRAL position.

• To prevent damage of the electric devices of the failed machine, turn the starting switch of the failed

machine to OFF position, check that the system operating lamp is not lit, and then turn the battery

disconnect switch key to OFF position and remove it before connecting the jumper cable.

For the operating method of the battery disconnect switch, see “BATTERY DISCONNECT SWITCH

(3-123)”.

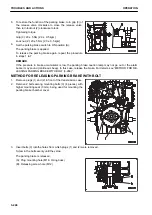

PROCEDURE FOR CONNECTING JUMPER CABLES

Turn the starting switch and battery disconnect switch of the failed machine, and the starting switch of the nor-

mal machine to OFF position.

OPERATION

TROUBLES AND ACTIONS

3-249

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...