TROUBLESHOOTING AND ELECTRICAL SYSTEM: FE400, KEY-START ENGINE

Test Procedures

Page 11-30

2006-2010 Turf/Carryall 272/472 and XRT 1200/1200 SE Maintenance and Service Manual

11

Test Procedure 16 – Ignition Coil, Continued:

4. If not previously tested, test the spark plug cap separately from the secondary coil.

4.1. Remove the rubber gasket (1) on the plug cap (2) by rolling back the gasket onto the spark plug

wire (3)

.

4.2. Remove the cap from the wire by turning the cap counterclockwise three or four revolutions while

gently pulling it off the wire

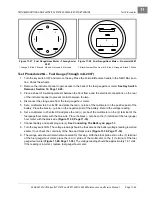

4.3. Using a multimeter set to 20k ohms, place the red (+) probe of the multimeter into the end of the

spark plug cap that normally connects to the spark plug and place the black (–) probe into the end

of the cap with the internal screw

. If the resistance is not between

4.5k - 6.0k ohms, the cap has failed and must be replaced. Proceed to the next step with the

spark plug cap still removed.

5. Test the secondary coil separately from the spark plug cap.

5.1. Using a multimeter set to 20k ohms, place the red (+) probe of the meter into the end of the spark

plug wire and place the black (–) probe on the core (2)

. If the resis-

tance is between 6.0k - 11.0k ohms, the secondary coil is within acceptable limits. If the resis-

tance is not between 6.0k - 11.0k ohms, the ignition coil has failed and must be replaced.

6. If the preceding procedures indicate that the ignition coil resistance readings are within acceptable

ranges, but the coil fails to function properly, replace the ignition coil and cap.

TEST PROCEDURE 17 – KEY SWITCH (ENGINE KILL CIRCUIT)

See General Warning, Section 1, Page 1-1.

1. Turn the key switch OFF and remove the key. Place the Forward/Reverse handle in the NEUTRAL posi-

tion. Chock the wheels.

2. Disconnect battery and spark plug wire(s).

See Disconnecting The Battery on page 1-3.

3. Remove the center dash assembly.

See Key Switch Removal, Section 12, Page 12-24.

4. Remove the connector from the key switch.

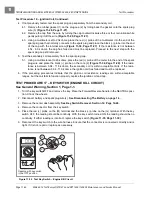

5. Place the red (+) probe on the (M) terminal and the black (–) probe on the (G) terminal. With the key

switch OFF, the reading should be continuity. With the key switch turned ON, the reading should be no

continuity. If either reading is incorrect, replace the key switch

.

6. Reconnect the key switch to the wire harness. Ensure that the connector is connected correctly and is

tight. If it is not, repair or replace as necessary.

Figure 11-35 Test Key Switch – Engine Kill Circuit

Reading with key switch

in the OFF position

2m

20

m

200

m

2k

200

200

200

200

20

2

200

m

500

20k

200k

2000

k

1000

OFF

WAVETEK

5XL

V

V

V

A

!

!

COM

200nA

MAX

1000 ---

750V

FUSED

M

B

L

G

S

Содержание CARRYALL 272

Страница 2: ......

Страница 14: ......

Страница 18: ...1...

Страница 52: ...5...

Страница 90: ...6...

Страница 110: ...7...

Страница 112: ...8...

Страница 128: ...10...

Страница 170: ...11...

Страница 224: ...13...

Страница 284: ...16...

Страница 302: ...17...

Страница 308: ......

Страница 309: ...Club Car R NOTES...

Страница 310: ...Club Car R NOTES...

Страница 311: ......