TROUBLESHOOTING AND ELECTRICAL SYSTEM: FE400, KEY-START ENGINE

Test Procedures

Page 11-24

2006-2010 Turf/Carryall 272/472 and XRT 1200/1200 SE Maintenance and Service Manual

11

Test Procedure 14 – Ignition Spark, Continued:

2.1. Adjust the tester probes to approximately to 18,000 volts (18 Kv) setting (SE –

Small Engine Setting

on the Thexton 404 tool). Connect the tester to the spark plug wire, and connect the alligator clip

to a solid engine ground.

2.2. Start the engine. There should be a strong blue spark between the probes of the spark gap tester.

If there is no spark, or if the spark is a faint yellow or red color, test components of the ignition circuit.

3. If the spark gap tester tool indicates a strong blue spark, it is possible the spark plug has failed internally.

Check the spark plug gap. The gap should be set at 0.027 to 0.031 of an inch (0.69 to 0.79 mm). If the

gap is correct, replace the spark plug with a new part and test the engine for proper operation.

TEST PROCEDURE 15 – RPM LIMITER

See General Warning, Section 1, Page 1-1.

1. Turn the key switch OFF and remove the key. Place the Forward/Reverse handle in the NEUTRAL posi-

tion. Chock the wheels.

2. Disconnect battery and spark plug wire(s).

See Disconnecting The Battery on page 1-3.

3. Disconnect both of the bullet terminals

.

4. Using a multimeter set to 200 ohms, place the red (+) probe on the brown ground wire and place the

black (–) probe on one of the black wire female bullet connectors. The reading should be no continuity.

If the reading is not correct, replace the RPM limiter.

5. This test will find most bad RPM limiters. Some of them may bench test okay but fail under a load due

to heat while operating. Another method of testing is to replace the RPM limiter and then run the engine.

If the engine runs properly, keep the new RPM limiter in the circuit.

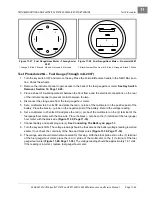

TEST PROCEDURE 16 – IGNITION COIL

See General Warning, Section 1, Page 1-1.

The following test procedures will properly detect a coil that has failed in most cases; however, in rare cases,

some ignition coils can fail to operate at normal (warmer) operating temperatures. If the ignition coil has

tested okay in the vehicle and on the bench, but fails to operate reliably, replace the coil with a known good-

coil and operate the engine for several minutes to ensure that the coil functions at normal operating temper-

ature. If the new coil functions properly, keep the new coil in the circuit.

Figure 11-23 Ignition Spark Test

Figure 11-24 Disconnect White/Black Engine Kill Wire

IGNITION GAP

TEST TOOL

SPARK PLUG

WIRE

SPARK PLUG

FRAME

Disconnect

white/black

engine

kill wire.

RPM

LIMITER

Содержание CARRYALL 272

Страница 2: ......

Страница 14: ......

Страница 18: ...1...

Страница 52: ...5...

Страница 90: ...6...

Страница 110: ...7...

Страница 112: ...8...

Страница 128: ...10...

Страница 170: ...11...

Страница 224: ...13...

Страница 284: ...16...

Страница 302: ...17...

Страница 308: ......

Страница 309: ...Club Car R NOTES...

Страница 310: ...Club Car R NOTES...

Страница 311: ......